Understand your system requirements

To have a durable and efficient hose assembly, it's crucial to understand your system requirements in relation to the application.

Start by analyzing the unique pressure needs, including both steady-state pressures and unexpected pressure surges. Misidentifying or failing to identify pressure needs can lead to early hose failure or, in the worst case scenario, hose burst.

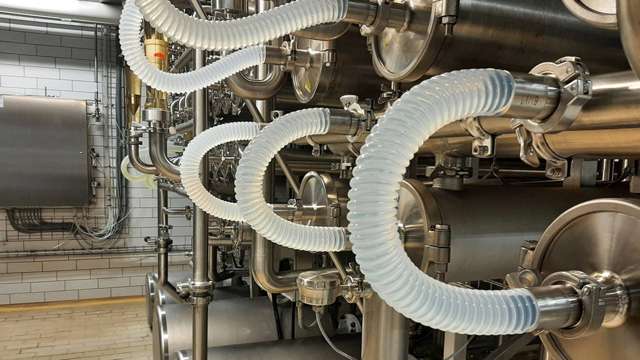

In vacuum applications, it's worth considering whether the hose can handle negative and positive pressure. Furthermore, it's important to take into account various environmental conditions, especially in specialized environments such as underwater applications, in hydraulic systems and chemical applications.

Consider the hose material

To ensure a hose is safe to use, it's important to choose the right hose material for the medium that will run through it. If the material is not compatible, the hose can be damaged.

Other external factors such as sunlight, pollution and ozone can also shorten the life of the hose.

If the hose creates static electricity, we have special hoses that can handle this, such as Air Food Antistatic and Dynamic Antistatic.

Find the bend radius

The bend radius is the minimum distance a hose can be bent without risk of damage or loss of performance.

At Alfotech, we carefully differentiate between static bend radius, where the hose remains motionless, and dynamic bend radius, where it is subjected to repeated movements.

Proper understanding and management of bend radius is important to avoid stress on the hose, ensure smooth flow and prevent production downtime.

Ensure correct dimensioning

To achieve optimal performance and extend the life of the hose assembly, it is essential to ensure proper sizing of fittings. Improperly sized fittings can lead to insufficient flow capacity and compromise the pressure integrity of the entire system.

Make sure to choose fittings that match the inner diameter of the hose to avoid bottlenecks or overloading, which can lead to leaks or ruptures.

If you choose our press-fit couplings, you get extra reliability due to our specially developed InterLock system.

Select the right rotation

In the context of hose assemblies, rotation refers to the orientation of the couplings at each end of the hose. It's crucial to ensure that the couplings are correctly aligned with the location on the process plant.

For example, a 90- or 270-degree rotation means that one coupling is oriented perpendicular to the other.

Correct coupling orientation is essential to maintain the efficiency of the hose and prevent undue stress on the joint.

da

da

de

de

en

en

sv

sv