Do you produce beer, wine or spirits? And are you considering replacing your process hoses?

The market selection of beer and beverage hoses for food production is extensive and often makes it challenging to find the right model for your needs. This time we make it a little easier for you and focus on our top candidates in the category, namely Beverage Plus, Beverage CLC/10 Crushproof and Liquorflex/SD.

We'll start at the beginning with the selection criteria you should be aware of and then dive into the differences and advantages of the process hoses. That way you'll be better prepared for your next purchase.

Read on and learn more!

5 features to consider when choosing

- Alcohol resistance: A high alcohol resistance protects process hoses from damage caused by highly alcoholic liquids, for example during the production of strong spirits. However, a process hose with low alcohol resistance can still be used for bottling wine or brewing beer. Each process hose has a maximum alcohol percentage it can withstand. Also note that it may be relevant to investigate electrical dissipation at high alcohol percentages due to possible explosion risk.

- Pressure tolerance: Working pressure is the maximum pressure the process hose is designed to withstand under normal operating conditions, while burst pressure is the point at which the hose will fail or rupture. As a safety precaution, burst pressure provides an extra margin above the working pressure.

- Temperature tolerance: Regardless of the intended use, the hose should be compatible with the working temperature of the process plant. For example, most process hoses for beer, wine or spirits production support intermittent high temperatures for SIP/CIP cleaning, but are usually used at lower working temperatures for fluid transportation.

- Chemical resistance: Often a range of chemicals are used to clean and disinfect the process hose, including alkaline and acid-based liquids. It’s important to make sure that the hose design supports the chemistry being used. For example, UPE (Ultra High Molecular Weight Polyethylene) is preferable to bromobutyl for very strong acidic or alkaline fluids.

- Flexibility: Does the process hose need to be able to be rolled up and withstand repeated movements? What about the space available in the installation area if it needs to be permanently mounted? The bend radius gives you a clue about the flexibility of the hose and the construction is crucial: with/without spiral, rubber type and compound, wall thickness etc.

Beverage vs. Liquorflex: Which one should you choose?

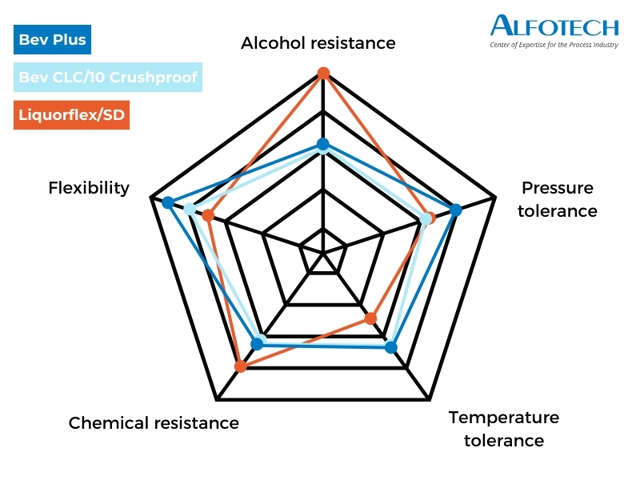

Our food-approved top candidates cover all needs in the production of beer, wine and spirits and are best-in-class. In the illustration above, we have compared them based on the previously described properties.

Beverage Plus

Beverage Plus is the ideal versatile hose solution for transporting beer and wine. Constructed without a spiral, with bromobutyl inside and EPDM outside, it’s highly flexible and durable. It’s especially suitable for tankers with hose reels. It can withstand temperatures from -40°C to +120°C and can be sterilized at 130°C for up to 30 minutes. Working pressure of 10 bar.

Beverage CLC/10 Crushproof

The term "ultimate robustness" is spot on when it comes to Beverage CLC/10 Crushproof. The hose is made of bromobutyl on the inside and corrugated neoprene on the outside. The built-in plastic spiral makes it flexible and resistant to kinking, crushing and mechanical damage (also available in steel spiral version). Especially suitable for production areas where there is a risk of collision. Covers temperature ranges from -40°C to +120°C and can be sterilized at 130°C for up to 30 minutes. Working pressure of 10 bar.

Liquorflex/SD

It can handle up to 98% alcohol and can therefore rightly be called "spirit king of them all". Specially constructed with UPE liner on the inside, synthetic rubber on the outside and reinforced with a steel spiral, Liquorflex/SD is the perfect choice for producing strong spirits. The built-in copper wires also ensure electrical dissipation to avoid the risk of explosion.

When we at Alfotech pre-assemble hoses for potentially explosive environments, we connect the steel spiral in the hose to the couplings to ensure that electrical charge is connected through the hose.

Configure as needed: Try the hose configurator

Did you know that you can quickly and easily configure your next process hose yourself? With our updated hose configurator on our website, you can create your Beverage Plus, Beverage CLC/10 Crushproof or Liquorflex/SD process hose in less than 2 minutes with dimension, length, number, fittings and any bends for each end. You can also specify the labeling you want and whether you want it pressure tested.

da

da

de

de

en

en

sv

sv