Art Briggs and Jack Streeter invented the flexible impeller pump back in 1938, a pump technology which would later become known as Jabsco. Today, Jabsco sanitary pumps are widely used across several industries, including high hygiene installations in the process industry. In this context, they are used for both thick and thin media, for example in dairies and in pharmaceutical companies, where safety and the environment are particularly important. Therefore, they often play a very important role in the process plant.

But how does the Jabsco sanitary pump actually work and how do you keep it running efficiently? We take a closer look at the popular pump technology.

The Jabsco pump and its benefits

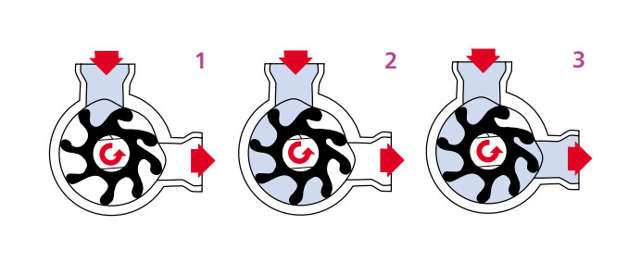

The Jabsco sanitary pump - also called an impeller pump – simply works in such a way that the air in the inlet pipe of a built-in impeller (rotor) is displaced (1), after which the medium is sucked in and transported (2) to the outlet at a steady flow rate (3).

The advantages of the Jabsco sanitary pump:

- Can pump both thick and thin media

- Compact size and versatile design

- Self-priming, even when dry

- Supports pulse-free flow

- Efficient and gentle handling of solid particles

- No air pockets or foam

- Easy and inexpensive maintenance

Impeller construction and variants

The impeller supports a wide speed range depending on the viscosity of the medium and is made of rubber compounds selected for their chemical compatibility.

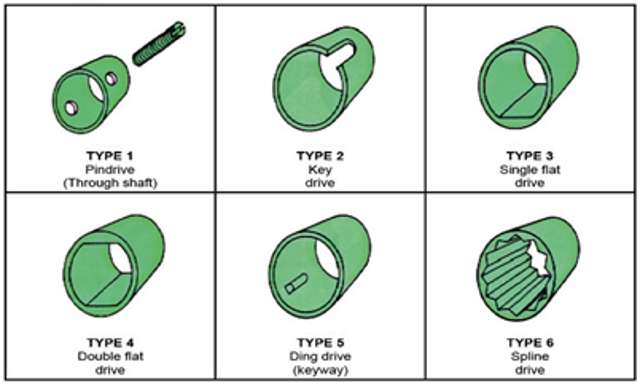

Rubber compounds include hygienic neoprene, nitrile, EPDM, and Viton. In addition, different versions of impellers are available depending on the type of shaft (see picture).

High quality Jabsco spare parts from Alfotech

Jabsco sanitary pumps are often critical to keeping production running, so it is important to have spare parts in reserve as to avoid costly downtime.

At Alfotech we stock high quality Jabsco spare parts including impellers, mechanical seals, O-rings, and wear plates. These food grade products in our range are very popular with our customers in the food and pharmaceutical industries. Maybe it was time to check if you have what you need? Please contact us by phone +45 7020 0422 or by e-mail alfotech@alfotech.dk - our sales consultants are ready to advise you.

da

da

de

de

en

en

sv

sv