Do you know what role pressure plays when choosing a new hose?

The pressure in a hose is critical to both its performance and safety. It's important to understand the difference between working and burst pressure and how they affect the durability and lifespan of the hose. And then there's the temperature issue...

Wouldn't it be helpful to have a clear understanding of these concepts so you can make better choices and improve your process plant's efficiency and safety?

In this edition of The Hose Selection Guide, we focus on the role of pressure in hose selection and how temperature also plays a role.

Working pressure vs. burst pressure: What's the difference?

When talking about hoses for industrial use, there are two terms you should consider: working pressure and burst pressure.

- Working pressure is the maximum pressure a hose can handle safely and effectively under normal operating conditions.

- Burst pressure is the point at which the hose can no longer withstand the pressure and will fail.

It's important to understand these concepts to ensure you choose the right hose for your needs and run a safe and efficient operation. If the hose doesn't meet the requirements, your production could come to a complete halt - in the worst-case scenario, it could result in fatal injury, especially during CIP cleaning, which often involves chemical liquids at high temperatures.

The effect of temperature on working pressure

Temperature has a crucial influence on a hose's resistance to working pressure.

As the temperature rises, the hose pressure often drops as a result. As a result, the strength of the hose material is reduced, and the hose becomes less resistant to the working pressure. For example, if you have a hose rated at 10 bar at 20°C degrees, the working pressure typically drops by 40% when the temperature reaches 90°C degrees. But this varies from hose type to hose type.

It's crucial to consider working temperatures along with pressure requirements when choosing the most suitable hose. Make sure it can withstand both the required working pressures and the expected working temperatures.

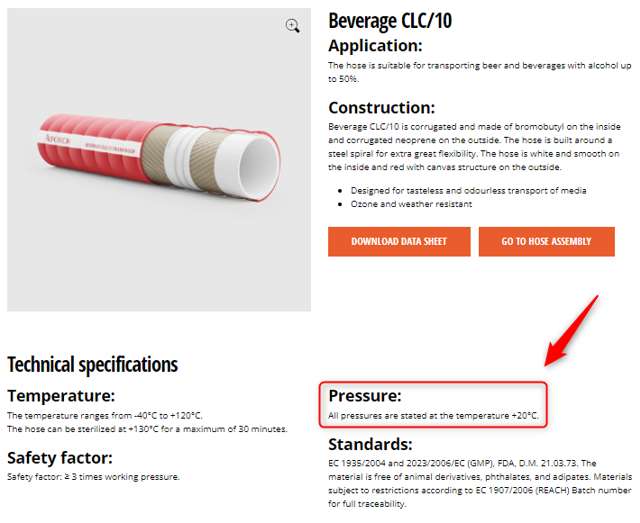

NOTE! Pressure information on a hose is always provided at a temperature of +20°C, for example as shown above on our website.

How we pressure test at Alfotech

Did you see Peter's Week with pressure testing of the hose?

Of course, quality assurance is important for us at Alfotech. Therefore, when hoses are shipped from our warehouse to the customer, a pressure certificate is often included. This provides an extra guarantee that the product meets the pressure requirements.

What's coming next?

In the next edition, we'll take a closer look at hose coupling types and their specific properties. We'll give you a simple overview and make you even better equipped to make the right hose choice!

da

da

de

de

en

en

sv

sv