Do you sometimes get confused about the different types of couplings on your process plant? Don't worry, you're not alone!

And yes, it can be a jungle to navigate and there can be many factors to consider when choosing the right ones. So in this edition of The Hose Selection Guide, we dive into the topic of hose couplings.

Not only do we give you a brief and concise overview of the hose coupling categories, but we also give you a crash course in the most common hose couplings available on the market today. That way, you'll be much better prepared for your next purchase decision.

Read on and learn more about the world of hose couplings!

What are hose couplings and why are they important?

Hose couplings are essential components used to connect industrial hoses to each other or other equipment. They play a crucial role in the process industry, ensuring the safe and efficient transfer of different types of media such as gases and liquids.

It's important to choose the right hose couplings to achieve a reliable connection and avoid leaks or unforeseen downtime. The material, size, and shape of the coupling are all important factors in its function and usability.

By choosing the right quality hose couplings and using them correctly, you can improve the efficiency of your operation and increase the lifespan of your industrial hoses. This can save you a lot of money in the long run!

Crash course in hose couplings

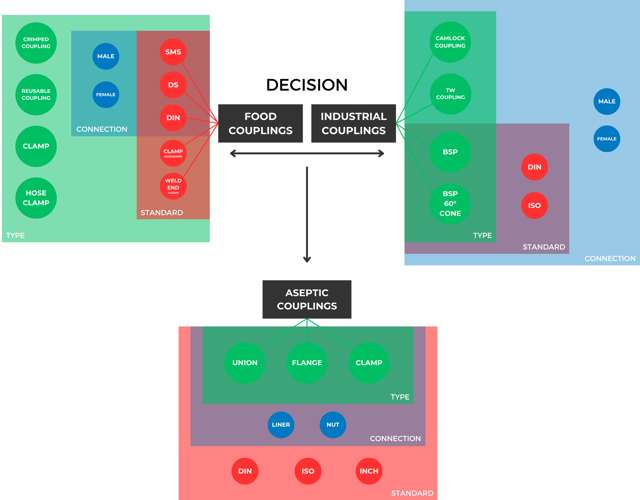

There are 3 main categories of hose couplings:

- Food couplings

- Industrial couplings

- Aseptic couplings

Within each of these, there are different types, connections, and standards.

In the illustration above, imagine that you are moving from the inside out when choosing the right coupling. For example, if you work with milk production and need to decide which coupling to use to connect the milk hose to the processing plant, you will use a food coupling.

Then ask yourself the following questions afterward:

- Which standard is it - SMS, DS, DIN, Clamp, or weld end?

- Which connection is it - male or female?

- Which type is best suited for your production – crimped coupling, reusable coupling, clamps, or hose clamps?

Type selection and benefits

To stay with the example, the different types of food couplings have their advantages:

- Crimped couplings: Ensure the highest hygiene and reliability. Strongest coupling joint.

- Reusable couplings: Ensure second-best hygiene. Interchangeable and most sustainable

- Clamps: Can be quickly replaced on site. Requires technical knowledge.

- Hose clamps: Flexible, easy, and inexpensive solution.

Always consider your needs, especially in relation to pressure and temperature, when choosing between coupling types. And of course, you can always contact us if you have any doubts🙂 Our consultants have it all under their belts and are ready to help!

What's coming next?

It's one thing to choose the right equipment, it's another to have the paperwork in order!

In the next and final edition of The Hose Selection Guide, we take a closer look at an often overlooked but crucial element in choosing the best industrial hose - documentation. We'll not only explain why it's so important for quality and traceability but also give you a real-world example.

da

da

de

de

en

en

sv

sv