Do you protect your production employees from dangerous fire damage when process hoses operate at high operating temperatures? And would you also like to extend the service life of your process hoses?

Then you should consider our new Pyroflex heat-resistant cover! With its robust construction and insulating property, it is the ideal solution for protecting both employees and process hoses against high temperatures and potential fires.

Read on and learn more!

What is a heat-resistant cover?

The heat-resistant cover is typically used to protect production employees from serious burns when touching process hoses that operate at very high operating temperatures. This could be in oil mills, steam installations or petrochemical plants, for example. In addition, the cover also helps to extend the service life of the process hose by shielding it from other external influences.

Due to its construction materials, it is not only effective in preventing heat transfer, but also relatively chemically resistant to a variety of substances.

Pyroflex: The versatile solution for every need

Pyroflex complies with the EN45545 and DIN5510-2 standards and is made of high-quality silicone-coated fibreglass. The construction ensures effective insulation of the heat from the medium in the process hose, making handling safer.

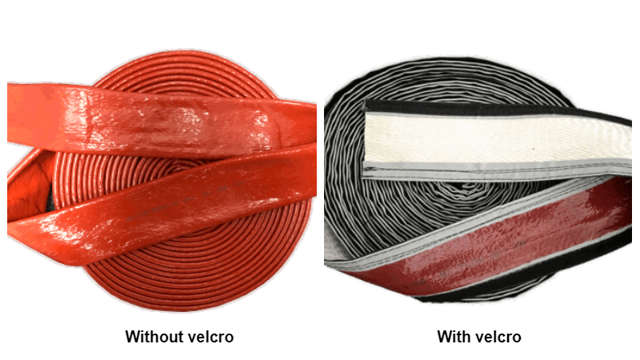

The red version without Velcro is the most affordable and is ideal for installation on brand new pipe or hose assemblies. However, if you need to heat protect an existing installation or regularly move the cover to other process lines, for example due to varying operating temperatures, the version with Velcro is the ideal choice. Both versions support a maximum temperature of 260°C, but can briefly reach up to 1100°C.

In other words, a versatile heat protection solution across the process industry.

Tailor-made hose solution via our assembly service

The specialists in our in-house assembly workshop work almost daily on custom assemblies. Due to our extensive know-how and expertise, there's really no limit to how complex the tasks can be. Learn more in the episode above from our video series Peter's Week.

When you let us assemble your hose solution, we place the cover without Velcro on the process hose and then close the ends by pressing stainless rings (as shown in the picture) onto the outside of the hose couplings. This ensures that there is no possible contamination during operation.

Still in doubt?

If you need further advice and guidance on fire protection for your process hoses, our experienced sales consultants are ready to talk about the possibilities with Pyroflex in relation to your specific needs. Give us a call on +45 7020 0422 or send us a quick email at inquiry@alfotech.eu.

da

da

de

de

en

en

sv

sv