Rubber hose guard

Smooth, available in different colors

Hose guard, 2-piece

Oil and grease resistant, available in different colors

Hose guard

Spiral shaped, resistant, available in multiple colors

Pyroflex heat-resistant cover

Max. 260°C, briefly up to 1100°C

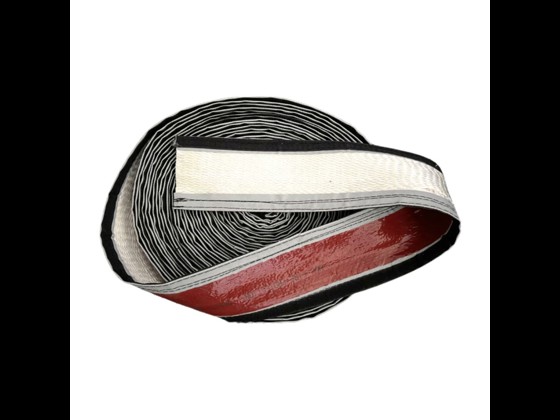

Pyroflex heat-resistant cover, Velcro

Max 260°C, briefly up to 1100°C

Extend the service life of your hoses and increase safety with hose protectors

In a busy everyday production environment – whether in the food or pharmaceutical industry – operational reliability is an important factor. Production depends on robust hoses that can safely transport critical media through the plant, regardless of whether they are exposed to thermal fluctuations or high-pressure levels. But what happens when your hoses rub against the floor, are hit by a forklift truck or exposed to extreme heat? Without the right protection, you risk costly production stoppages and dangerous working conditions for your employees.

Why is hose protection an advantage in production?

Mechanical impact is the most common cause of premature failure of industrial hoses. This can be anything from hoses rubbing against concrete floors to accidental impacts from tools or machines. A transparent structure in your maintenance and use of the right protective equipment ensures that your production runs smoothly.

We always recommend hose protection as a key part of your hose maintenance. By choosing the right solution, you shift the wear away from the hose itself and onto a reusable component. It is both cheaper and faster for you to replace a protector than to have to reinstall a complete hose assembly.

Mechanical protection: From spirals to nitrile rubber

We offer a wide range of mechanical protection designed to withstand the specific stresses of your process environment. By choosing the correct type, you ensure optimal protection of both hose and coupling.

Spiral hose protectors in polyethylen

Our spiral protector is manufactured by extrusion from high-density polyethylene, which helps to give you a solid breaking strength.

- Gentle design: The naturally round spiral edges ensure that the protector does not damage the hose itself.

- Flexible size: The design allows one protector to cover multiple hose dimensions, making it easier for you to choose the right size.

- Chemical resistance: The material is resistant to acids, oils and solvents, giving your hoses extra protection against chemical influences in the process.

Smooth rubber hose protectors for flushing systems

For tasks where your equipment is exposed to constant wear and tear under extreme conditions, we offer a smooth hose guard in flexible and strong nitrile rubber.

- Specially designed for couplings: These are specifically designed to protect couplings and hose assemblies on flushing and foaming systems.

- High resistance: Created to withstand the high pressures and temperatures that characterise industrial cleaning processes.

2-piece hose guards for easy retrofitting

If you want to extend the service life of your existing industrial hoses without dismantling the installation, take a look at our 2-piece solution in nitrile rubber. They are designed to withstand heavy wear during both production and subsequent cleaning cycles. The smart thing is that you can retrofit them on any existing industrial hose if the need for protection arises later.

Would you like to hear more about our range of hose protectors and the benefits of using them? Then watch this video, where we present them one by one.

Colour coding: Create an overview and increase control in your production

We can supply our hose protectors in several different colours. When you choose solutions in different colours, you not only get a visual marker; you get an extra layer of control in your daily production.

The colours make it easier for your operators to maintain an overview and create structure, which is beneficial when you need to quickly identify:

- Hose types and functions: Easily distinguish between steam, chemical or food hoses, for example.

- Production areas and zones: Ensure that equipment remains in the correct zones.

- Maintenance or cleaning status: Use colours to indicate when a hose was last inspected.

With a colour-coded approach, you not only organise your production more intelligently, but you also reduce the risk of human error. Whether you work with cleaning systems or process lines, colour coding makes it easier for your team to navigate, act and document processes correctly.

Pyroflex: Protection against extreme temperatures

While our other products focus on handling mechanical wear, Pyroflex stands out as a dedicated solution for thermal protection. Where a plastic spiral protects against floor wear, Pyroflex is designed to handle the hazards posed by extreme heat and fire.

In environments with steam installations or very hot pipes, you must prioritise the safety of your employees. Pyroflex is a heat-resistant hose cover made of silicone-coated fibreglass that can withstand temperatures up to 260°C. It is available with or without Velcro.

If you are unsure which variant is best suited to your installation, we present the difference in this video.

Hose protector for your specific needs

Do you need guidance on which hose protectors are best suited to your production?

Our experienced team of specialists is transparent in helping you find the most effective solution to protect your hoses and reduce the risk of downtime and maintenance. We are experts in helping companies find the best solutions for their needs.

Contact us at inquiry@alfotech.eu or call us on +45 7020 0422, and we will be happy to help you find the best hose protection for your production.

Frequently asked questions

Why is hose protection an advantage?

When hoses are constantly hit by floors, edges, forklift forks or tools, they deteriorate much faster than their construction intended. A hose guard acts as a controlled ‘wear part’ that can be replaced quickly and inexpensively, so that the hose itself and operations are protected as much as possible.

How do we protect existing hoses without dismantling the system?

Here, 2-part protectors are interesting because they can be ‘clipped’ around a hose that is already installed in the system. This makes it possible to reinforce exposed sections – e.g. near floors and machines – as a targeted upgrade without having to replace the hose assembly.

When is Pyroflex the right choice?

In areas with steam, very hot pipes or a risk of flames, heat protection is at least as important as mechanical wear resistance. Here, a silicone-coated Pyroflex hose cover is relevant because it protects both the hose and employees from high surface temperatures. You can choose with or without Velcro, depending on how flexible the installation needs to be.

da

da

de

de

en

en

sv

sv