Sanitary gaskets for food & dairy couplings

DS, SMS, DIN, Clamp, IDF, RJT, MINI Clamp etc.

Union gaskets with screens

SMS, DIN, Clamp etc.

Butterfly valve gaskets

Pasilac & SPX, Alfa-Laval, AWH etc.

Plug for sampling

For Alfa-Laval, Keofitt and APV/SPX

Mechanical seals

APV, Alfa-Laval, Fristam, SSP, Johnson etc.

Cartridge seals

LSC40-F & LDC40 Double

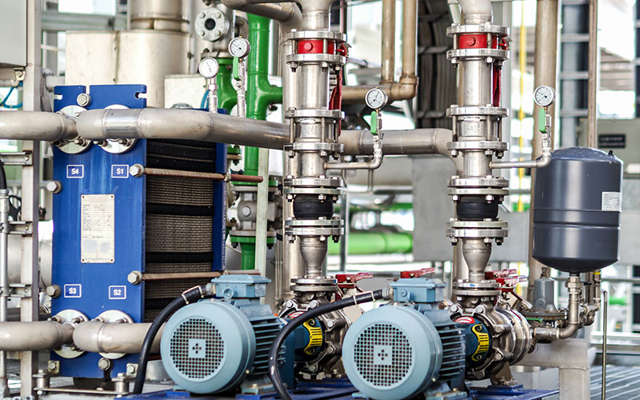

Gasket and mechanical seal – complete range for the process industry

We offer a comprehensive range of gaskets and mechanical seals designed to meet the high demands of modern process industry. Our solutions are used particularly in food, pharmaceutical and chemical production, where hygiene, operational reliability and easy maintenance are paramount. With decades of experience in the industry, we specialise in putting together sealing solutions that are precisely tailored to your specific operating conditions – regardless of complexity.

We are experts in technical consulting and customisation. We develop many of our solutions in close dialogue with customers and based on specific process requirements. That is why we are always transparent to help – whether you need standard gaskets, customised mechanical seals or simply technical advice.

What is the difference between gaskets and mechanical seals?

Gaskets and mechanical seals play a crucial role in ensuring tight and controlled processes in industry.

- Gaskets are typically used for static joints – e.g. between pipes and fittings – where they prevent the leakage of liquids and gases. They are available in many standards such as DS, SMS, DIN, Clamp, IDF and RJT and ensure hygienic transitions in sensitive environments.

- Mechanical seals, on the other hand, are used for dynamic seals where shafts rotate, as seen in pumps, agitators and mixers. They prevent the medium from escaping around rotating components, while ensuring that no unwanted particles or bacteria enter the process.

Both types of seals are critical for avoiding downtime, extending equipment life and maintaining stable production.

The most popular sealing solutions

We offer a wide range of sealing products for different purposes and types of equipment. Among the most commonly used solutions are:

Sanitary gaskets and butterfly gaskets

Sanitary gaskets are available in all common standards and are widely used in CIP/SIP processes. They ensure fast and secure sealing between pipe components. Butterfly gaskets are used in valve connections, where they provide high sealing performance and durability – even under changing temperature and pressure conditions. We stock gaskets for valves from Alfa-Laval and AWH, among others.

Mechanical seals for process equipment

We offer OEM-compatible mechanical seals for a wide range of pumps and machines. For APV pumps, we have sealing solutions for models such as W, W+, WS+, C-series and SRG. For Alfa-Laval, we cover the FM, LKH, MR and Contherm series. In addition, we offer seals for Inoxpa pumps as well as Jabsco Hy-Line lobe pumps – all with a choice of O-ring materials to perfectly suit your media and environment. ljø.

Cartridge seals for demanding operations

When processes require maximum sealing under high pressure and temperature, cartridge seals are the solution. Our LSC40-F single seal and LDC40 double cartridge seal combine robust construction with compact design. They are available in materials such as AISI 316 and Hastelloy and can be used up to 200 °C and 25 bar. The seals are ideal for both food production and chemical applications.

How to choose the right seal

The choice of seal should always be based on the process conditions. We place great emphasis on understanding the environment in which the seal will operate – from the chemical composition and temperature of the medium to requirements for cleaning and durability.

If the process is based on CIP or SIP, the seal must be able to withstand frequent and intensive cleaning cycles. Materials such as PTFE or EPDM are typically recommended here. For aggressive media, viton/FPM may be necessary.

It is also important to ensure that the seal matches the manufacturer's specifications. All our sealing products are OEM-compatible and ensure correct fit and performance, regardless of make. If you need help identifying the right model, we are happy to assist you with the selection – this applies to both current and discontinued pump models.

Please contact our specialists by email at inquiry@alfotech.eu or give them a call on +45 7020 0422 – they will be happy to help you.

Would you like to know more about how a mechanical seal works and why the material is so important?

In this video, we go through the basic principles: from the difference between rotating and stationary surfaces to the importance of liquids and material choices such as car, ceramics and silicon carbide.

Materials and technical specifications

We stock a wide range of high-quality sealing products so that you can quickly find the solution you need

The mechanical seals can be combined in a number of friction pairs – e.g. car against stainless, car against ceramics, car against silicon carbide or wear-resistant combinations such as Tc/Tc. These combinations ensure optimal sealing under varying loads and rotation.

The rubber components are available in several qualities – including NBR, EPDM, viton (FPM) and PTFE – depending on the characteristics of the medium and the operating environment. The same materials are also used in our comprehensive gasket range.

Frequently asked questions

What is the difference between gaskets and shaft seals?

Gaskets are used to seal static joints – typically between pipes and fittings – while shaft seals are used around rotating parts such as shafts in pumps and mixers.

Are the seals food-approved?

Yes, we have access to many OEM specifications and can supply seals for both new and older models from APV, Alfa-Laval, Jabsco and Inoxpa, among others.

What are the advantages of choosing a cartridge seal?

Cartridge seals are easy to install, have a compact design and ensure effective sealing under demanding conditions with high pressure and temperature. They are also easier to replace and maintain than traditional mechanical seals.

What does OEM compatibility mean in practice?

OEM compatibility means that our gaskets and mechanical seals are designed to fit directly into equipment from the original manufacturers – without the need for adaptation or modification. This ensures that the seal can be installed one-to-one in, for example, APV, Alfa-Laval, Jabsco or Inoxpa equipment and delivers the same functionality and reliability as the original part. This gives you a solution that is easy to replace, minimises the risk of incorrect installation and reduces production downtime.

da

da

de

de

en

en

sv

sv