DS union gaskets

NBR, EPDM, Viton, PTFE - Standard: FDA/USP

SMS union gaskets

NBR, EPDM, Viton, PTFE - Standard: FDA/USP

DIN union gaskets

NBR, EPDM, Viton, PTFE - Standard: FDA/USP

Aseptic union gaskets

DIN, EPDM - Standard: FDA/USP

Clamp union gaskets, ISO

NBR, EPDM, Viton, PTFE - ISO 2852, FDA/USP

Mini Clamp union gaskets

NBR, EPDM, Viton, PTFE - Standard: FDA/USP

Clamp union gaskets, DIN

NBR, EPDM, Viton, PTFE - Standard: FDA/USP

IDF union gaskets

NBR L-shape, EPDM L-shape, NBR T-shape, EPDM T-shape - FD...

RJT union gaskets

NBR, EPDM - FDA/USP, BS 4825

Union gaskets – Features, benefits and applications

Sanitary gaskets are essential sealing components in process plants where tightness, hygiene and operational reliability are paramount. They ensure reliable sealing between pipes and fittings in piping systems that are typically exposed to stresses from CIP or SIP cleaning, temperature fluctuations and aggressive media. The gasket is placed between two mating surfaces and acts as a barrier against both the medium and external influences. In food and pharmaceutical production, where cleanliness and documentation requirements are particularly high, union gaskets play a key role in ensuring product quality and operational reliability. Even minor leaks or breakdowns can have major consequences for both production and food safety, which is why choosing the right gasket is just as important as the rest of the plant design.

Union gaskets are therefore critical components, as a leaky gasket can halt the entire production process. Watch the video and find out why union gaskets are indispensable in your spare parts inventory.

The most commonly used standards for union gaskets

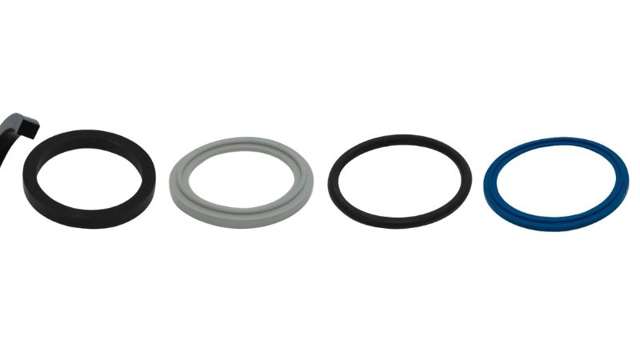

We offer union gaskets in a wide range of standards so that you can find the solution that fits your process plant perfectly. Our range includes DS, SMS, DIN and Clamp in ISO and DIN standards, which are among the most widely used coupling systems in the food and pharmaceutical industries. In addition, we also offer union gaskets in aseptic designs, Mini Clamp variants and gaskets in accordance with IDF and RJT standards. For process plants with special requirements, we also offer union gaskets with integrated screens.

Common to all these standards is that they differ in geometry, assembly principle and compression requirements, which has a major impact on how the gasket must be adapted. Choosing the wrong type can lead to leaks, uneven pressure distribution or impaired hygiene. It is therefore crucial that the gasket matches the exact standard, both in form and function. If you need help identifying which standard your pipe and fitting systems comply with, we are always transparent and ready to guide you and ensure the right choice – whether for a new plant or an existing installation with mixed standards.

How to choose the right union gasket

When choosing the right union gasket, you should first and foremost consider the medium being transported through the system. Is it oily, acidic, alkaline or temperate? Each property places specific demands on the material's resistance and flexibility. Next, you should consider cleaning methods, especially if the plant is cleaned using CIP processes involving high temperatures and aggressive cleaning agents. Documentation requirements are also important to include in the decision, as FDA approval is often required for particularly sensitive production processes. Finally, the plant design and coupling type influence both the standard and material selection. The right combination of standard, material and documentation minimises the risk of downtime and ensures consistent production.

Materials for union gaskets and their properties

We offer union gaskets in a range of different materials, each developed to match specific process environments and requirements.

- NBR is a classic solution for oil-containing products and organic liquids. It has good resistance to grease and mineral oils and is well suited to non-aggressive environments. However, it has its limitations in contact with acids, bases and CIP cleaning with high pH.

- EPDM, on the other hand, performs very well in alkaline environments. It is resistant to steam, hot water and strong cleaning agents, making it a good choice for food production where CIP systems are an integral part of everyday life. However, it should be avoided where there is contact with oil or solvents.

- Viton is a chemical-resistant material that can withstand acids, solvents, CIP and high temperatures, making it ideal for demanding processes.

- PTFE is a chemically resistant material that can withstand acids, bases and solvents. It has a smooth, non-porous surface, making it ideal for hygienic processes with high cleaning requirements. However, it lacks flexibility and should therefore only be used in static assemblies without large pressure fluctuations.

Frequently asked questions

Which food specifications do union gaskets comply with?

All our union gaskets comply with FDA. This ensures that they are approved for use in food contact and are supplied with full documentation and traceability.

When should a union gasket be replaced?

A union gasket should be replaced when it loses its elasticity and thus its ability to ensure tightness. Elasticity is gradually reduced over time due to temperature and chemical influences. The higher the temperature and the longer the gasket is in service, the faster the degradation. Therefore, replacement should be carried out as soon as signs of deformation, weakened tightness or changed shape appear, even if the gasket is not visibly worn.

Which material is best for CIP cleaning?

Most of our materials can be used for CIP cleaning. EPDM is often the preferred choice as it has high resistance to alkaline chemicals, high temperatures and pressure fluctuations. Viton performs well in environments where both acids and bases are present and where temperature tolerance is also required. PTFE is also used in systems with aggressive chemicals, but here you should be aware of temperature and pressure fluctuations. NBR is not suitable for repeated exposure to chemicals and is primarily used in more neutral cleaning environments.

da

da

de

de

en

en

sv

sv