Single-use couplings

Produced and packaged in cleanroom, ISO-7 quality

Single-use assemblies

Produced and packedaged in cleanroom, ISO-7 quality

Single-use solutions for pharma and biotech

Single-use technology has changed workflows in the pharmaceutical and biotechnology industries in just a few years. In an everyday environment with increased focus on flexibility, documentation, and cleanliness, more companies are choosing to replace classic steel installations and heavy CIP/SIP cleaning methods with single-use couplings. We offer a wide range of sterile, single-use couplings and customized assemblies that ensure efficient and safe fluid handling in your GMP-regulated processes.

Our solutions are developed with high traceability and production safety in mind. Everything is assembled and packaged in ISO 7 clean rooms and delivered with the necessary documentation, making it easy for you to comply with regulatory requirements.

What is single-use technology?

Single-use technology involves replacing reusable components, e.g. stainless steel, with sterile single-use solutions that are used once and then disposed of. This minimizes the need for cleaning and validation between batches, significantly reducing the risk of cross-contamination.

In practice, this means that instead of cleaning and re-qualifying equipment between productions, you simply switch to new sterile components. This is an advantage in production environments with:

- Many variants and short series.

- High requirements for documentation.

- Need for flexibility in both planning and daily operations.

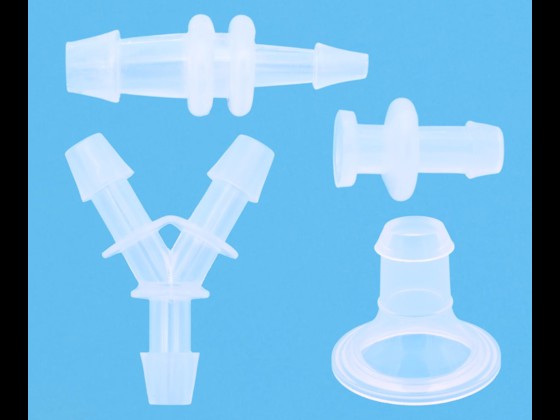

Our range of single-use couplings

Among the most widely used products in our range are couplings made of polypropylene. They are designed to ensure sterile, tight connections and are available in several designs, including straight couplings as well as Y, T, and cross configurations. They can be easily integrated into your existing systems where it is necessary to maintain a sterile product path.

The single-use solutions are delivered as complete assemblies, assembled and packaged under strictly controlled conditions in ISO 7-certified clean rooms. By ensuring low particle concentration and high product safety right from the production stage, you receive a solution that is completely transparent for use – without the need for further assembly or validation.

Our single-use couplings are developed with a focus on quality, safety and compliance with applicable international standards. The products comply with FDA 21 CFR 177.1520 and are tested in accordance with USP <87> and <88>. This ensures that they meet the requirements of, among other things, the GMP framework.

Tailor-made assemblies for your needs

Single-use assemblies differ from standard components in that they are tailor-made solutions that are assembled specifically for each individual customer and process. For example, an assembly may contain a combination of couplings, filters, and manifolds that together form a complete process connection.

We assemble and package assemblies that are produced in ISO 7-certified clean rooms to ensure low particle concentration and high product safety. When you receive the solution, it is transparent for use without the need for further assembly or validation.

Single-use assemblies are often used in critical process steps such as pre-use post-sterilization integrity testing (PUPSIT), aseptic sampling, and other sensitive applications where there is no room for compromise in terms of either cleanliness or documentation.

Advantages of single-use in production

The biggest benefit of the technology is the time savings and flexibility it brings to your production. The advantages include:

- Significantly reduced downtime, as components do not need to be cleaned and re-qualified between batches.

- Faster changeovers between different products or campaigns.

- Less complexity and fewer risks for your QA and production technicians, as each batch starts with a new and sterile product contact surface.

- Elimination of residues from previous productions, making it easier for you to document that process safety is intact batch after batch.

- Reduced investment and operating costs, as the need for CIP/SIP equipment, utilities and cleaning chemicals is reduced.

Frequently asked questions

What is the difference between components and assemblies?

Components are individual standard parts, such as couplings, fittings or hoses, which can be used separately in a single-use setup. Assemblies are pre-assembled and often customised, combining several components into a complete solution for fluid flow. Assemblies are delivered assembled and transparent for use.

Why is an ISO 7 cleanroom important?

An ISO 7 cleanroom ensures that the assembly and gasketing of single-use couplings and assemblies take place in a controlled environment with low particle and microbiological levels. This reduces the risk of contamination and is a prerequisite for the products to be used in sterile and aseptic pharmaceutical and biotech processes.

When should single-use technology be chosen?

Single-use technology is particularly relevant for frequent product changeovers, smaller batch sizes, and in multi-product facilities. The solution reduces the need for CIP/SIP, minimizes downtime, and simplifies documentation and validation, making it suitable for processes where flexibility and operational reliability are key requirements.

da

da

de

de

en

en

sv

sv