Y-connector PP

Produced in cleanroom, ISO-7 quality

T-connector PP

Produced in cleanroom, ISO-7 quality

Straight connector PP

Produced in cleanroom, ISO-7 quality

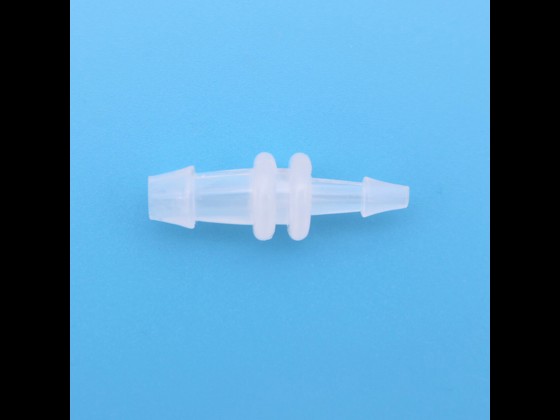

Reducer PP

Produced in cleanroom, ISO-7 quality

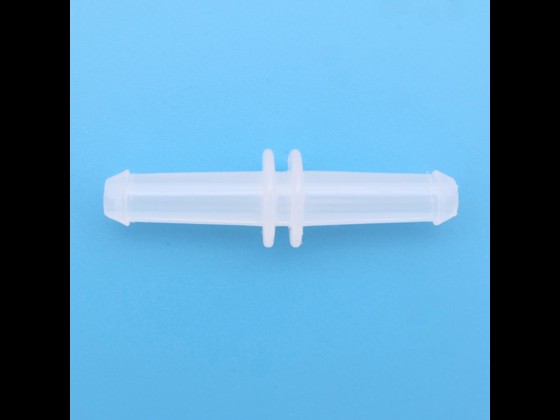

MINI Clamp connector PP

Produced in cleanroom, ISO-7 quality

Clamp connector PP

Produced in cleanroom, ISO-7 quality

Cross connector PP

Produced in cleanroom, ISO-7 quality

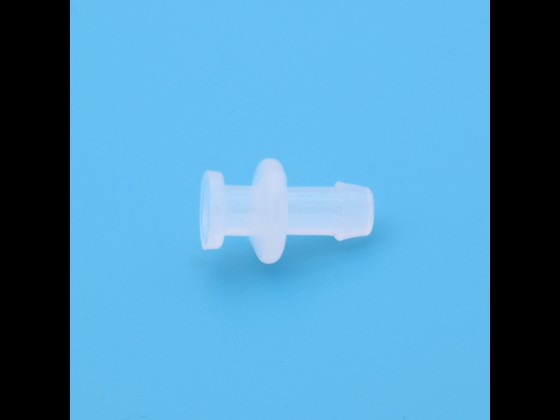

Clamp end cap PP

Produced in cleanroom, ISO-7 quality

End plug PP

Produced in cleanroom, ISO-7 quality

Hygienic single-use couplings for biopharmaceutical and pharmaceutical production

Are you looking for single-use couplings for your business? We have the solution. Our couplings are designed to meet the requirements of biopharmaceutical and pharmaceutical production with a focus on quality and safety.

Single-use couplings are ideal for many manufacturing companies as they ensure efficiency and maintain hygiene standards in various production processes. Our products comply with all relevant certifications and approvals, and we guarantee high safety when they come into direct contact with medical products or food.

What are single-use couplings?

Imagine being able to skip the tedious cleaning and still maintain a sterile process. Single-use couplings are designed for single use, eliminating the time-consuming cleaning stage. Each batch starts with a new, untouched coupling, ensuring the highest level of purity. Made from durable PP plastic, these couplings offer both durability and chemical resistance. Once connected, you get a secure connection that prevents contamination.

In biopharmaceutical and pharmaceutical production, single-use couplings have revolutionised changeovers between productions, increased flexibility and reduced downtime. Try them with our Silicone Hose, Platinum, Cleanroom to optimise your hygienic conditions.

Material selection: Polypropylene in challenging environments

Our product range includes single-use couplings specifically designed for demanding production environments. Do you need couplings that can withstand chemical influences? Then our single-use couplings are the right choice. They are made of PP, which is known for its strength and durability, while also having good chemical properties.

Polypropylene is the preferred material for couplings used in production with aggressive substances, which is why our couplings are ideal for the strict safety requirements of the biopharmaceutical and pharmaceutical industries.

Certifications and approvals for optimal safety

Our single-use couplings are designed to meet the applicable requirements and international standards for the biotech and pharmaceutical industries. They are certified to FDA 21 CFR 177.1520, USP <88> and <87>, and comply with RoHS and REACH. This ensures that you get products that meet the highest standards of purity, biocompatibility and environmental responsibility. Our single-use couplings are free of TSE/BSE, which means that they can be used safely in direct contact with medical products or food.

We have many years of experience as a supplier of components to the pharmaceutical industry and specialise in providing the necessary documentation and certifications required for your production.

Advantages in pharmaceutical production

By using single-use couplings in pharmaceutical production, you gain a number of advantages that improve efficiency and safety. With each new coupling, the chance of cross-contamination is reduced, which is crucial in an industry where even small errors can have major consequences. To maintain high hygiene standards, these couplings are supplied in double-packaged bags produced in clean rooms.

Single-use couplings also offer flexibility and scalability, allowing you to quickly adapt your production. Whether you need to increase production or change product lines, these couplings enable quick changes without extensive cleaning or equipment modifications.

Frequently asked questions

Can single-use couplings be used in all pharmaceutical processes?

Yes, they can easily be integrated into a wide range of pharmaceutical process steps, from production to packaging. Their versatility makes them the ideal choice for a wide range of applications, including fluid transfer and mixing.

How do single-use couplings prevent cross-contamination?

As single-use components, they offer a fresh and clean part for each production cycle, eliminating the risk of residues from previous processes. The robust design ensures a hermetic seal and effectively protects against unwanted particles. Single-use couplings ensure a safe production process where product quality and purity standards are maintained.

How do the couplings ensure aseptic handling?

They are supplied double-packed in cleanroom quality (ISO‑7), which protects against contamination during transport and storage. The sterile packaging allows the couplings to be connected directly in the process environment without additional handling.

What applications are single-use couplings suitable for?

They are primarily used in biopharmaceutical production, including liquid transfer, sampling, media and buffer handling – especially where sterility and documentation are crucial.

da

da

de

de

en

en

sv

sv