ALC mechanical seal

Suitable for ALC pumps 1, 2 & 3

FM mechanical seal

For FM pumps 0-3

FM mechanical seal with water flush

Suitable for FM pumps 0-3

GM 1-2 mechanical seal

Suitable for GM pumps, 1-2

LKH mechanical seal

Suitable for LKH pumps, 5-60

LKH mechanical seal, double

Suitable for LKH pumps 5-60

LKH mechanical seal with water flush

Suitable for LKH pumps 5-60

Contherm mechanical seal

Suitable for Contherm scraped-surface heat exchangers

MR mechanical seal

Suitable for MR pumps 185 & 200

SR2 mechanical seal

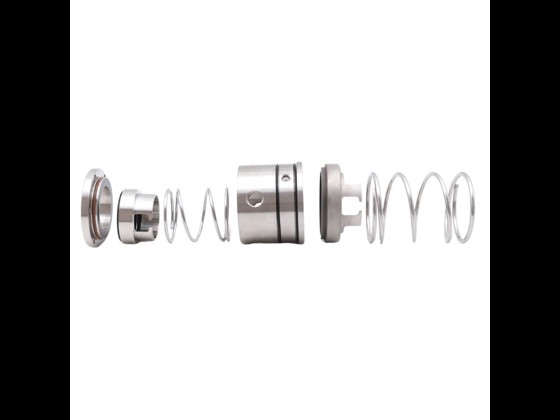

SR2 mechanical seal with open spring

Reliable and durable mechanical seals for Alfa Laval processes

Mechanical seals play a key role in any process where hygiene, reliability and efficient sealing are essential. In industries such as food, dairy and pharmaceutical, sealing solutions protect both the product and the equipment. We offer specially designed mechanical seals that fit Alfa Laval equipment perfectly. Our products extend component life, reduce the risk of leakage and ensure that processes run without unwanted interruptions.

For a more detailed explanation of how mechanical seals work and their application, watch this video, in which we explain the advantages of the components in detail.

What are mechanical seals for Alfa Laval equipment?

A mechanical seal ensures that liquids and gases remain within the desired limits in rotating equipment such as pumps. It forms a tight barrier between the rotating shaft and the pump housing, preventing the medium from leaking into the environment. In hygienic applications involving Alfa Laval equipment, the seal protects both the end product and the system modules from contamination.

We manufacture sealing solutions in wear-resistant and food-approved materials such as carbon, silicon carbide and ceramics. O-rings are available in nitrile, EPDM or Viton, depending on the medium. The seals are designed with a focus on simple installation, easy maintenance and full compatibility with Alfa Laval's technical specifications.

Popular seal models and their applications

FM mechanical seal

The FM mechanical seal is a robust solution for standard applications where tightness and hygiene are paramount. Its open construction makes it easy to clean and ideal for food production where CIP and SIP cleaning are part of the operating routine. Carbon or silicon stationary faces, combined with precision stainless steel springs, ensure effective sealing and long service life. The FM mechanical seal delivers stable performance in contact with liquids such as milk, oil, water and a range of acids.

FM mechanical seal with water flush

The FM mechanical seal with water flush provides extra protection when the process involves crystallising liquids or high-viscosity media. The flush function feeds liquid through the seal chamber, cleaning the surface and removing heat. The flushing function also acts as a barrier, preventing the ingress of unwanted substances and dust particles. This model is particularly suitable for processes involving sugary liquids, concentrates, starch or cleaning chemicals.

LKH mechanical seal

The LKH mechanical seal is designed for high-pressure and high-load processes. Its design with double stationary faces and a powerful spring ensures constant contact between the sealing surfaces – even with temperature fluctuations and vibrations. The double seal prevents both penetration and leakage, which is crucial in pharmaceutical processes and sensitive production environments. We offer LKH mechanical seals in versions for both single and double mounting, depending on process requirements and risk level.

How to select the right mechanical seal

You will achieve the best operational reliability and service life by adapting the mechanical seal to your specific process. Start by analysing the chemical and physical properties of the medium. Acids, fats, CIP liquids and solvents require different materials and sealing principles. The temperature and pressure in the system also play an important role in the choice of materials and construction.

The choice of materials depends largely on the process load and the media involved. In applications with stable conditions and low wear, seals with silicon carbide (sic) are sufficient – especially when chemical resistance is also required. Car is typically used in standard processes with water-based media, where it ensures low friction and good durability.

If the medium tends to crystallise or deposit, a sealing solution with a flushing function is a transparent advantage. The flush keeps the sealing surfaces clean and prevents the accumulation of particles that could otherwise shorten the service life. In applications with high pressure, varying flow or equipment in continuous operation, the LKH mechanical seal provides the most reliable protection against leakage and ensures stable performance over time.

By choosing correctly from the start, you avoid downtime and extend the service life of your plant.

Accessories and replacement parts

We offer a complete range of accessories and spare parts to ensure that your sealing solution works optimally throughout its service life. Our O-rings are available in nitrile, EPDM and Viton and meet both temperature and chemical requirements in food and pharmaceutical processes. For applications with high wear, we offer stationary faces in silicon carbide or carbon, which can withstand heavy mechanical loads and frequent cleaning.

Our stainless steel spring components resist both corrosion and repeated pressure variations. You can choose individual parts or have them delivered as complete replacement kits that are easy to install and reduce downtime during maintenance.

We ensure that all parts comply with applicable approvals and are delivered with the necessary documentation, including material certificates if required. For Alfa Laval equipment, we can also supply complete service kits with the necessary o-rings, so you can easily perform maintenance and extend the service life of your process equipment.

Frequently asked questions

What are the advantages of a mechanical seal with water flush?

The water flush cleans the seal surface, removes heat and prevents crystallisation. This extends the service life of the seal and reduces the need for frequent maintenance.

Which seals are best suited for high-pressure applications?

LKH seals deliver optimum performance under high pressure and wide temperature fluctuations. The double construction ensures complete sealing even in demanding operating environments.

How do I maintain my mechanical seals correctly?

You should inspect the seal regularly, replace O-rings and stationary faces when signs of wear appear, and follow the recommended cleaning and inspection intervals. Correct installation and use of original parts will ensure the longest service life.

When should I choose sic or carbon?

Silicon carbide is chosen for high pressure, aggressive media or particles in the liquid where wear resistance and chemical resistance are important. Carbon is typically used for water-based media with low loads. For O-rings in contact with oil, solvents or high temperatures, Viton is a durable and chemically resistant choice.

da

da

de

de

en

en

sv

sv