JOHNSON OL mechanical seal

For pump types 1, 2, 3 & 4, non-directional

JOHNSON Top Wing mechanical seal

For pump types TW1, TW2 and TW3, non-directional

JOHNSON Acculobe mechanical seal

With Viton gasket, non-directional

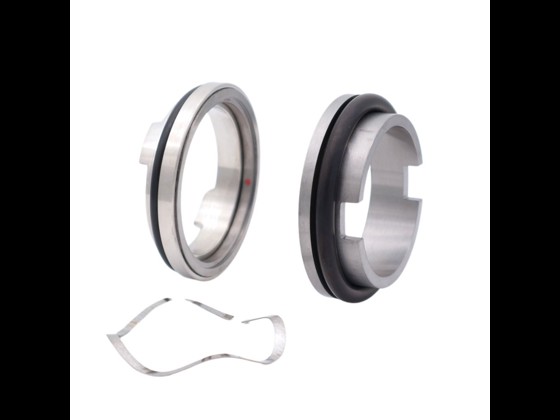

JOHNSON Sterilobe mechanical seal

With stainless steel spring, non-directional

Customised mechanical seals for Johnson lobe pumps

When lobe pumps are used in processes with high demands on cleanliness and product safety, the sealing solution becomes an essential part of operational reliability. Lobe pumps can handle a wide range of media and are particularly suitable for viscous, sensitive and particle-laden media. They handle everything from thin liquids such as oil and water to thicker products such as mayonnaise, syrup and creams – without damaging the structure. The pumps also handle media with solid particles, such as yoghurt with fruit pieces. The combination of low pulsation and high suction capacity makes them an obvious choice in food, cosmetics and pharmaceutical production.

We offer customised shaft seals that are compatible with the most commonly used Johnson models. They are designed to meet the requirements for both chemical resistance and temperature tolerance, while ensuring simple installation and effective sealing over time.

If you would like a more detailed explanation of how mechanical seals work and their application, watch this video, in which we go through the components step by step.

Product overview – four sealing solutions for Johnson lobe pumps

Johnson OL

Johnson OL is compatible with OL pumps in sizes 1 to 4, is driven by two pins and held securely in place with an O-ring and slots. The design is non-directional and the pressure spring is located externally. With stationary and rotating seats available in various materials such as carbon, silicon, tungsten (wolfram) and stainless steel, as well as Viton® seals, there are several options for optimising service life based on the product in the pump.

Johnson Top Wing

Johnson Top Wing mechanical seals fit TW1, TW2 and TW3 lobe pumps and are based on the same basic principles as the OL variant. Johnson Top Wing is an ultra-hygienic pump designed for demanding environments and easy maintenance. We offer shaft seals in different variants. The rotating part is available in silicon or carbon, while the stationary part is only available in silicon.

Johnson Acculobe

The Acculobe mechanical seal has a compact design without a wave spring and focuses on effective sealing via an O-ring and two slots that hold the seal unit in position. With rotating and stationary parts in silicon and gaskets in Viton®, it is suitable for sensitive media and temperature-sensitive processes. An obvious choice in installations where operational reliability and hygiene go hand in hand.

Johnson Sterilobe

Johnson Sterilobe is combined with a wave spring, external pressure spring and O-ring system with materials made of silicon and Viton®. The rotating part is driven by two pins and is available in either carbon or silicon. The solution is non-directional and therefore works flexibly in various mounting scenarios with high leak safety and long service life.

Choose the right Johnson seal

The choice of seal should reflect the nature of the medium, the cleaning requirements and the mechanical environment in which the seal will operate. For Johnson pumps, it is essential to choose a seal that not only matches the geometry of the lobe pump, but can also withstand frequent cleaning procedures and aggressive fluids. We offer solutions that are designed as direct replacements for the original components, making them easy to install without modification. In addition, we can advise on material selection based on your specific process.

Additional components and documentation

When replacing or upgrading, we recommend assessing the sealing system as a whole. O-rings in alternative materials, customised slide rings or seats in different hardnesses may be necessary to ensure optimal performance. We are also happy to provide documentation, material certificates and technical specifications, which are often required for audits in food and pharmaceutical production.

Frequently asked questions

Are the seals compatible with Johnson's original components?

Yes. The four models mentioned have been developed as replacement seals and fit directly into the pump types in question.

What materials are used in sealing surfaces and gaskets?

We use carbon and silicon slide rings, seats in silicon, steel or TC, and gaskets in Viton. The choice depends on the medium and operating requirements.

Are the seals approved for use in the food industry?

Yes, the materials are suitable for contact with food, and we can provide the necessary documentation on request.

Which seal should I choose for high-temperature processes and frequent cleaning?

The Johnson Top Wing and Sterilobe models are suitable for this type of application as they use wear-resistant materials and have designs that can withstand thermal and chemical stress.

da

da

de

de

en

en

sv

sv