Oily Food/10

Flexible, without spiral, 10 bar

Oily Food/SPL

Highly flexible, steel spiral, 10 bar

Oily Food/SPL Crushproof

Impact resistant, plastic spiral, 10 bar

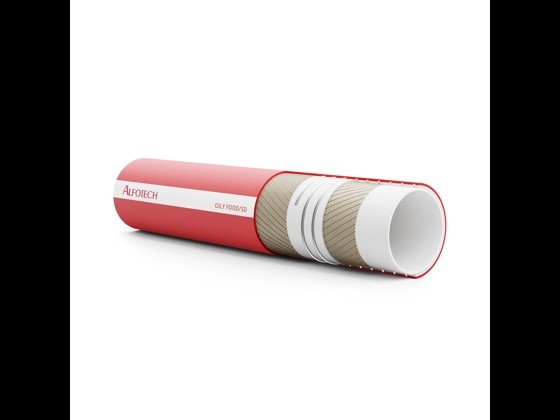

Oily Food/SD

Highly flexible, steel spiral, 16 bar

Oily Food/10-SLIDE

Dirt-repellent (UPE-coated), without spiral, 10 bar

HOT Oily Food/10-FLEXPERFORMANCE

Corrugated, highly flexible, 2 x steel spiral, 10 bar

Lightfood/SD

Lightweight and extra flexible, steel spiral, 96% alcohol

Flexible and food-grade hoses for oil and fat-based food products

When transporting fatty or oil-based food products, it is essential to use hose solutions that are safe, durable and approved for contact with food. We offer a wide range of high-quality food hoses for oil and fatty products, specially developed for the demands of food production. Whether you work with dairy products, edible oils or sauces, you can find a solution that matches your flow requirements, pressure level and temperature resistance. The hoses are tested and documented in accordance with food safety standards and can be easily combined with fittings and couplings through our intuitive hose configurator. You get flexibility, hygiene and operational reliability all in one product. Transparent, ready for fast delivery and adapted to your production conditions.

What makes our hoses ideal for oil and fatty foods?

Our oil and grease hoses are made of nitrile rubber (NBR) and neoprene, which provide high resistance to vegetable and animal fats. The inner rubber core is odourless and tasteless, making it ideal for sensitive foods, while the outer construction protects against thermal and mechanical wear. The models range from flexible hoses with fabric reinforcement to extra-strong versions with steel spirals, ensuring high operational reliability regardless of production requirements. With operating temperatures from –20 °C to +90 °C, the hoses are suitable for both cold and hot media. Working pressures from 10 to 80 bar and burst pressures with a safety factor ≥ 3x make them suitable for everything from standard to high-pressure systems.

Certifications, materials and documentation

All our hoses are food-approved and comply with relevant international standards such as EC 1935/2004, FDA 177.2600 and BfR. They are manufactured in accordance with GMP principles and contain no animal derivatives, phthalates or adipates. To ensure full traceability, all products are marked with a batch number, and we offer certificates and documentation that match both internal quality requirements and external audit processes. This makes it easy to document compliance and ensure hygiene across production. If you have any questions about specific approvals or additional documentation, our experts are always available to advise you.

Choosing a hose and areas of application

The choice of food hose depends on factors such as the type of medium, pressure conditions, temperature and flexibility requirements. Oily Food/10 is suitable for most fatty foods and standard applications with low to moderate pressure. Oily Food/SPL is more flexible and is our most popular hose for fatty and oily products. Oily Food/SPL is used in the production of ice cream, sauces, cooking oils, minced meat and many other types of food. Oily Food/SPL is also available in a Crushproof version, which is designed with a plastic spiral that makes the hose resistant to impact. HOT Oily Food/10‑Flexperformance is the most temperature-resistant hose and is often used in connection with equipment with high thermal requirements. With our online hose configurator, you can quickly put together the optimal solution including fittings, length and diameter. In addition, we offer hose refurbishment through our assembly workshop, which is both sustainable and significantly reduces the cost of new hoses.

Accessories and complete installation

We offer a comprehensive range of food-approved hose couplings in DS, DIN, ISO, Clamp, Mini Clamp and several other standards to match the various hoses in our range. Our hose configurator allows you to configure complete installations directly on the website, so you get a solution tailored precisely to your needs. By combining our hoses with the right couplings, you achieve both operational reliability and hygiene. We are always available to provide technical advice if you have any questions about component selection or require special adaptations.

Frequently asked questions

How do I choose the right hose?

Start by identifying the medium to be transported and the pressure, temperature and flexibility requirements. Then select a model that meets these criteria. Feel free to use our hose configurator, which provides a visual and technical overview of the possible combinations. You are also welcome to contact our technical advisors for individual advice.

What certifications do the hoses come with?

Our hoses are tested and food-approved in accordance with applicable standards, including EC 1935/2004, FDA and BfR. In addition, we can offer REACH compatibility and production in accordance with GMP principles. Certificates and declarations of conformity can be provided as standard or on request.

Can documentation be provided?

Yes, we offer documentation such as batch numbers, material specifications, declarations of conformity and certificates. These can be enclosed directly with the delivery or sent digitally, depending on your requirements and audit situations.

How do you maintain the hoses?

We recommend visual inspection and proper storage to extend service life. Avoid sharp kinks, mechanical overload and exposure to unsuitable chemicals, as this may impair the properties of the hose over time.

Which foods are the hoses suitable for?

The hoses can be used for a wide range of oily and fatty products such as vegetable oils, butter, mayonnaise, dairy products and sauces. The smooth, non-absorbent rubber core ensures that the product retains its taste and quality without contamination.

da

da

de

de

en

en

sv

sv