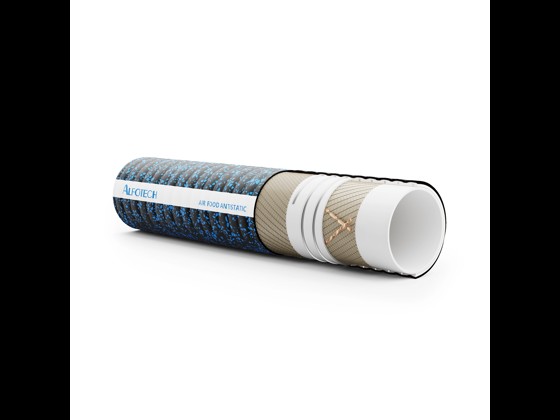

Air Food Antistatic

Flexible, FDA-approved, steel spiral

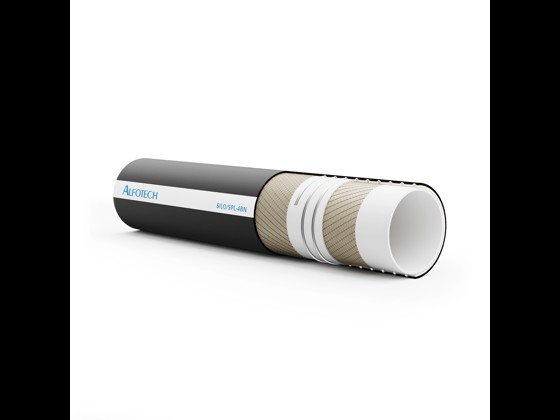

Silo/SPL-4BN

Electrically dissipative, FDA-approved, steel spiral

Granofood/CLC/4

Electrically dissipative, highly flexible, PU liner, stee...

Hoses for collecting granules and powder

When working with granules, powder or other dry materials, it is important to choose a hose that matches both the medium and your system. Granule hoses are typically used in vacuum or pressure systems, where they transport material from silos, containers or directly from the machine. This applies regardless of whether you produce food, animal feed or work in pharmaceutical production.

You should always choose a hose based on the material to be transported. Dry and abrasive products such as flour, grain and sugar wear heavily on the hose and require high wear resistance. At the same time, the material behind the hose must be able to withstand temperatures, physical impacts and possible contact with food.

Three high-performance granulate hoses

Our range includes a choice of three granule hoses. They all feature a strong steel spiral and antistatic construction with copper wire, which ensures proper dissipation of static electricity.

- Air-Food Antistatic is a flexible suction and pressure hose for powdered foods such as sugar, flour and milk powder. The inner core of NBR rubber is tasteless, and the outer layer of synthetic rubber with a canvas imprint provides robustness and flexibility. The hose has an electrical resistance of less than 10⁸ ohms and dissipates static electricity via embedded copper wire. Temperature resistance: −20 °C to +90 °C, and can withstand short-term sterilisation at +130 °C for minutes. Air-Food Antistatic is suitable for food applications where both hygiene and flexibility are required.

- Silo/SPL-4BN is designed for use in transport systems with powder and granules, including flour, animal feed and grain. The hose is made of natural rubber and reinforced with high-strength walls and a steel spiral. The light, smooth inner surface ensures a stable flow, while the black outer surface resists both ozone and weathering. The hose can withstand operation in temperatures from -30°C to +60°C and briefly up to +80°C.

- Granofood/CLC/4 is a robust granule hose, developed for tasks with high demands on wear resistance and flexibility. It is suitable for media such as sugar, grain and powder, and is often used in environments where the hose is exposed to mechanical stress and vibration. The smooth polyurethane inner surface provides good flow, while the outer surface is made of synthetic rubber with a canvas imprint for increased durability. You can use the hose in temperatures from -35°C to +100°C and sterilise it at +130°C for up to 30 minutes.

Effective flow and reduced risk of blockage

An important property of granule hose is that it must ensure a consistent and uninterrupted flow. All three of our hoses are equipped with a smooth inner surface that reduces friction and prevents powdered materials from clumping or sticking. This is particularly important in systems where large quantities of flour, sugar or feed products are transported.

The steel spiral, which is part of the hose construction, protects against compression and deformation and ensures that the hose retains its shape – even under sharp elbows and stress from external influences.

Tailor-made solutions adapted to your needs

We offer both standard solutions and customised granule hoses that match the requirements of your production. Our range covers several diameters, lengths and coupling types, and with our online hose configurator, you can quickly and easily find the solution that suits your needs. Select the hose type, enter the dimensions and specifications, and the system will present you with the combinations that meet your requirements.

If you have any questions about choosing hoses, couplings or documentation, our technical specialists are ready to advise you on pressure, temperature, material compatibility and regulatory requirements. With more than 40 years of experience in the process industry and a strong understanding of the needs of the food sector, feed industry and technical plants, we can help you find a solution that both works in practice and meets the standards. Call +45 7020 0422 or write to inquiry@alfotech.eu, and we will be in touch.

Frequently asked questions

Which granule hose is best for abrasive media such as flour or grain?

All our granule hoses are suitable for abrasive media as they are made of durable materials and have good mechanical strength.

Are your granule hoses food-approved?

Yes, our granular hoses are food-approved and suitable for contact with powdered foods such as flour, sugar and milk powder.

How is static electricity dissipated from the hoses?

All three hoses have built-in copper wire and are made of antistatic materials. They must be properly earthed during installation to dissipate static electricity.

What are the temperature limits for the hoses?

Depending on the model, the operating temperature ranges from -35°C to +100°C. Air-Food and Granofood/CLC/4 can be sterilised at up to +130°C for short periods.

Can the hoses be supplied with couplings and adapted to specific systems?

Yes, we offer both standard and customised solutions to suit different coupling types and process systems. Please contact us for advice.

da

da

de

de

en

en

sv

sv