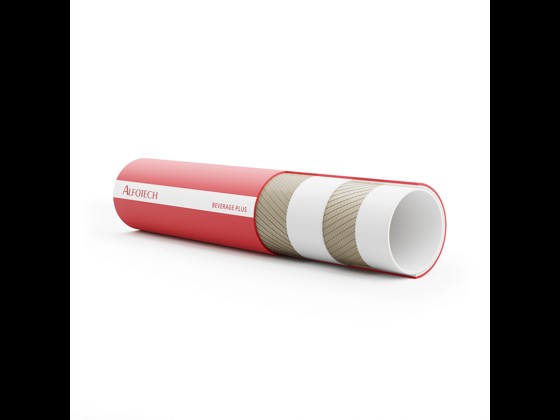

Beverage Plus

Flexible, without spiral, 15 bar

Beverage CLC/10

Corrugated, highly flexible, steel spiral, 10 bar

Beverage CLC/10 Crushproof

Corrugated, impact resistant, plastic spiral, 10 bar

Beverage/SPL

Highly flexible, steel spiral, 15 bar

Unifood Flexperform

Corrugated, highly flexible, steel spiral, 16 bar

Liquorflex/SD

Electrically dissipative, steel spiral, 98% alcohol

Profiline Aqua Plus

Flexible and elastic, KTW approved, 16 bar

ACQUA/ADT-K

Drinking water hose, flexible, made of TPE

Bacco FF

Transparent and smooth, red PVC spiral

Top-quality beer and beverage hoses for industrial use

We offer a wide range of beer and beverage hoses, developed to meet the high demands of modern food production. The hoses are, of course, food-approved and designed to withstand chemical stress, pressure and temperature fluctuations.

Our beverage hoses are made from durable and flexible materials such as EPDM, UPE and bromobutyl, with and without steel spiral. This means you get a foodhose that can withstand both pressure and vacuum, while being easy to handle in production. All models are CIP-cleanable, making them perfect for continuous operation in breweries, bottling plants and other beverage industries.

Selected hoses from our product range

Whether you produce beer, wine, spirits, soft drinks, juices, energy drinks or other beverages, we offer hose solutions that ensure hygienic, efficient and safe fluid handling.

Beverage CLC/10

Beverage CLC/10 is a flexible food hose with a built-in steel spiral that combines high pressure resistance with easy handling in daily operation. The inner liner in bromobutyl ensures a taste-neutral transfer of liquids, while the outer red neoprene cover protects against wear and external influences. The hose works in both cold and hot processes up to +120°C. In addition, it can be sterilised at +130°C for short periods, making it ideal for CIP cleaning.

Beverage CLC/10 Crushproof

The Crushproof is tailored for production environments with physical stress such as driving and tight packing, where hoses with steel spirals are vulnerable to being run over. Our Crushproof food hose uses a strong plastic spiral that makes the hose resistant to being run over without compromising flexibility. The bromobutyl inner layer is suitable for taste and air-free transport and makes it easy to clean, while the outer layer protects against wear and tear. Temperature range from -40°C to +120°C.

Unifood Flexperform

Unifood Flexperform is the obvious choice when flexibility and resistance are required for the transport of wine, juice, beer and fatty liquids. It is constructed with a steel spiral, an inner layer of natural rubber and neoprene, and an EPDM outer layer that can withstand chemical stress and provides mechanical protection. The food hose is approved for up to 16 bar operating pressure and is therefore ideal for installations where higher pressure is required – e.g. in breweries and bottling plants that work with beer with a high hop content. The hose can handle temperatures up to 90°C and can be sterilised with steam at +130°C.

Liquorflex/SD

Liquorflex/SD has been developed for handling spirits and alcohol up to 98% and is therefore the obvious choice for distilleries and producers with high demands on safety and product quality. The smooth UPE inner surface preserves the taste of the liquid, while the steel spiral and built-in copper wire ensure strength and antistatic discharge in explosion-sensitive areas. The wear-resistant exterior makes it robust against both mechanical impact and daily operation. Liquorflex/SD is available in sizes from 19 to 102 mm and works efficiently in temperatures from –35 °C to +90 °C.

Breweries rely on us

Thanks to our extensive expertise and delivery capability, many Danish and foreign breweries place their trust in us. As in so many other places, maintaining operations in breweries is crucial, as a breakdown can cost a lot of money. With our extensive experience in the industry, we know what it takes to create the most reliable solutions for all types of production facilities, and it is precisely this insight that makes us the preferred supplier in the industry. Read here, for example, how we provided emergency assistance to a large Danish brewery with new hoses after an accident during CIP cleaning.

User-friendly solutions with our hose configurator

Are you in need of food-grade hoses for beer and beverage production? We offer a wide range of high-quality hoses, carefully selected in collaboration with reliable suppliers and adapted to the requirements of the modern food industry. With our online hose configurator, you can easily configure hose type, dimension, length and couplings – including the option of labelling and documentation. Orders are processed quickly and we usually deliver from day to day.

Frequently asked questions

What is the difference between a food hose and a regular industrial hose?

A food hose is made of materials that are approved for contact with food and do not impart taste, odour or harmful substances. Regular industrial hoses must not be used for food production as they do not meet the same requirements.

Can Crushproof be used in running production environments?

Yes, it has been specially developed to withstand mechanical stress such as running, pressure and compression. This makes it particularly suitable for lines with mobile trolleys, roller tables or dense palletising.

What should I be aware of when transporting alcohol?

When handling alcohol, especially above 13%, antistatic hoses such as Liquorflex/SD should be used. It dissipates static electricity and is approved for transporting alcohol with an alcohol content of up to 98%.

Can all hoses be sterilised?

Yes, all four models can be sterilised – typically up to +130 °C for 30 minutes. This also makes them suitable for CIP cleaning in continuous production.

How do I choose the right hose diameter?

It depends on the flow requirements, pressure and how flexible the installation needs to be. We are happy to advise you and have several sizes in stock to suit both small bottling plants and large production facilities.

da

da

de

de

en

en

sv

sv