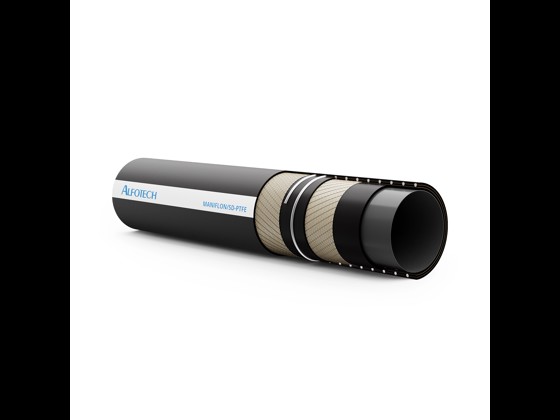

Maniflon/SD-PTFE

Antistatic, PTFE liner, steel spiral, 16 bar, ATEX approved

Manichem/SD-UPE

Antistatic, ATEX approved, UPE liner, steel spiral, 16 bar

Manichem/SD-EPDM

Antistatic, suction and delivery hose, 16 bar

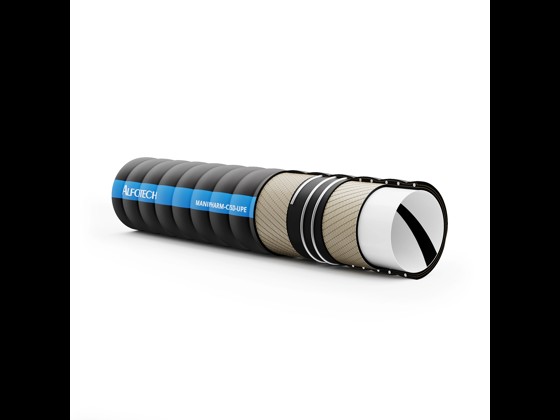

Manipharm-C/SD-UPE

Resistant to harsh chemicals, UPE liner, steel spiral, 10...

Alichem CLC/10

Corrugated, FDA approved, CIP compliant, steel spiral

Alichem/SPL

Flexible, FDA approved, CIP compliant, steel spiral

Alichem

FDA approved, CIP compatible, without spiral

HOT Alichem/BN-S

Antistatic, FDA approved, CIP compliant, without spiral

Prochim SPL/10-UPE

Antistatic, ATEX approved, UPE liner, steel spiral

Chemical hoses for the process industry: Reliable and long-lasting operation

In production lines where aggressive media and high temperatures are part of everyday life, chemical hoses are much more than just a component. They are a prerequisite for stable operation and safe handling of chemicals. Here you will find an overview of how materials, construction and choice of chemical hose interact, and how to find the solution that suits your needs.

What are chemical hoses?

Chemical hoses are flexible pipes designed to transport chemicals safely under varying process conditions. They are widely used in industries such as food production, pharmaceuticals, chemical industry and environmental technology. The purpose is to ensure controlled handling of both aggressive and non-aggressive chemicals, while at the same time the hoses must be able to withstand pressure, temperature changes and mechanical wear.

They are available in different versions depending on the medium and environment. Some models are optimised for CIP processes with steam, others are antistatic and ATEX approved. The common denominator is reliable transport and long service life in complex systems.

Chemical safety starts with the right choice

The choice of chemical hose should always be based on the medium, the environment and the operating conditions in which the hose will be used. Here is an overview of four specific types – each with its own properties and applications.

Alichem CLC/10 – Flexible solution in EPDM

Alichem CLC/10 is a chemical hose made of EPDM rubber, suitable for aggressive chemicals and vapour. EPDM ensures high temperature tolerance and chemical resistance, contributing to safe operation in demanding environments. The hose is also flexible and easy to install, even where space is limited. Its high wear resistance extends its service life and reduces the risk of downtime. Alichem CLC/10 is often used in CIP installations.

Manipharm C/SD UPE – For sensitive chemicals

Manipharm C/SD UPE is constructed with an inner layer of UPE (ultra-high molecular weight polyethylene), which has excellent chemical resistance. The hose is ideal for high-purity media, as its construction reduces the risk of cross-contamination. It is antistatic and therefore suitable for environments where static electricity can occur.

Manichem SD UPE – Robust and versatile

Manichem SD UPE is a versatile chemical hose, also with UPE as the inner material. It resists both acidic and alkaline chemicals and serves as an all-round solution where pH values vary. The built-in antistatic helix strip makes it safe in potentially explosive environments where reliability is critical.

Maniflon SD PTFE – Maximum resistance

Maniflon SD PTFE is designed for transporting the most aggressive chemicals. The PTFE inner layer provides exceptional chemical resistance. The hose is flexible, easy to install and both antistatic and ATEX-approved, making it suitable for environments with a high risk of ignition.

Material selection and specifications – how to choose the right chemical hose

The choice of material has a direct impact on operational safety. Chemical resistance and durability are closely related to the internal structure of the chemical hose.

The properties of the material determine the performance of the hose:

- EPDM: Good resistance to heat, steam and a wide range of chemicals. Provides high wear resistance and flexibility.

- UPE: Provides high chemical resistance and is suitable for sensitive media with purity requirements.

- PTFE: Extreme chemical resistance – ideal for aggressive and corrosive substances in demanding environments.

Several of the chemical hoses are also available with antistatic properties and ATEX approval. This is necessary in potentially explosive areas where static electricity can pose a risk.

When looking for the optimal solution, you should also clarify which chemicals are to be transported, what pressure and temperature the hose must be able to handle over time, and whether the hose will be exposed to bending, vibrations or other mechanical influences.

A good choice starts with accurate data. That is why we recommend using our hose configurator – a tool where you can enter specifications such as length, diameter and media type and see the most suitable hose solution for your specific setup.

Do you need advice? We are happy to help you find a solution that matches your requirements. Call +45 7020 0422 or write to inquiry@alfotech.eu, and we will be happy to talk to you.

Frequently asked questions

What chemicals can chemical hoses handle?

Chemical hoses are designed to handle a wide range of chemicals – both acidic and alkaline substances as well as solvents such as acetone, ethanol and benzene. To ensure durability and safe operation, you should choose a chemical hose that is compatible with the specific media you are working with.

How do you maintain chemical hoses?

Proper maintenance extends service life and ensures stable performance. You should regularly inspect the hose for wear, cracks and damage, check that fittings and connections are tight and free of corrosion, and ensure regular cleaning according to applicable instructions so that chemical residues do not accumulate and degrade the material.

How do I choose the right chemical hose?

The right choice depends on the chemicals to be transported and the pressure and temperature conditions under which the hose will operate. You should also take into account any mechanical influences such as bending and vibrations. Our hose configurator makes it easy to enter the necessary data and view relevant solutions for your specific production environment.

When should a chemical hose be replaced?

A chemical hose should be replaced if it shows signs of reduced flexibility, cracks, damage or leaks. This also applies if antistatic properties or ATEX approvals can no longer be guaranteed. Planned replacement can be an advantage if you want to avoid unexpected downtime and maintain stable production.

da

da

de

de

en

en

sv

sv