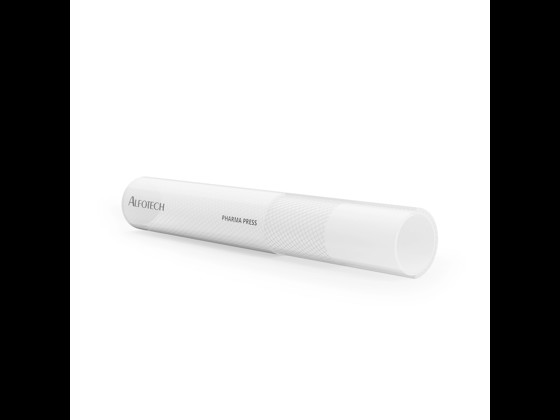

Pharma Press

Flexible, FDA-approved, transparent, without spiral

Pharmasteel Press

Flexible, FDA-approved, transparent, steel spiral

Crystal Clear 55

Suitable for hose pumps, durable, FDA approved

Thermoplastic hoses – Features, advantages and applications

Our range includes thermoplastic hoses (TPE) developed to meet the high demands of food, pharmaceutical and biotechnology production. Our selection consists of transparent hoses with proven chemical resistance, high temperature tolerance and great flexibility – all delivered in top industrial quality.

Why choose thermoplastic hoses for your production?

Thermoplastic hoses made of TPE stand out by combining high flexibility, low weight and chemical resistance – properties that make them ideal in hygiene-sensitive and demanding environments. The transparent hoses allow for good process monitoring and can withstand temperatures from -30 °C to +100 °C, making them suitable for both hot and cold applications.

Compared to PVC hoses, they are more energy efficient and easier to install, while meeting international requirements for food and pharmaceutical production. This makes them an obvious choice in CIP processes and production lines where safety, hygiene and documentation are crucial.

Differences between the most commonly used models

We offer several variants of thermoplastic hoses, which are adapted to different technical requirements and environments. Our Pharma Press model is made of TPE-S and is characterised by high flexibility, transparency and chemical resistance. It is particularly suitable for transporting foodstuffs, alcoholic media up to 96% and cosmetic and pharmaceutical products, such as spirits and vinegar. The hose is oil and grease resistant under normal conditions of use and can be used in a wide temperature range.

For installations with particularly high pressure and abrasion resistance requirements, we recommend Pharmasteel Press, for example for transporting milk powder, where we fit the hose with an earthing cable for extra safety. This model is reinforced with stainless AISI 302 steel spiral and polyester fabric and combines robustness with flexibility.

Both hose types are food-approved and support efficient and safe production.

Choose the right hose for your application

When choosing a hose, it is important to take into account the type of medium, temperature and operating pressure – especially in environments with chemical resistance and certification requirements. Many breakdowns are caused by misjudged burst pressure and insufficient safety factor. Our technical guide provides an overview of capacity requirements and helps you make a safe and efficient choice.

Accessories and documentation included in the solution

All our thermoplastic hoses are FDA approved and USP Class VI certified and come with accompanying documentation and pressure test certificates for assembled hoses. This means that they comply with both national and international standards for food contact and pharmaceutical applications. We also advise on the selection of fittings and accessories for your solution – for example, couplings in stainless steel in DIN, ISO, CLAMP and many other types. With the right combination of hose and our high-quality hose couplings with interlock system, you get a long-lasting and reliable installation that reduces the risk of leaks, kinks and downtime.

Frequently asked questions

How long does a thermoplastic hose last?

It is difficult to give a definitive answer to the question of how long a hose will last, as this depends on several factors such as the operating environment, temperature, pressure and correct installation. These factors have a direct impact on the durability of the hose.

What materials are used in thermoplastic hoses?

The most commonly used are TPE, TPU and TPE-S. These combine flexibility, chemical resistance and temperature tolerance and are used in everything from CIP processes to liquid transport in pharmaceutical and food production.

What is the difference between thermoplastic and rubber hoses?

Thermoplastic hoses are lighter, more transparent and easier to install. Rubber hoses typically have higher abrasion resistance but often require more maintenance.

What is the SAE 100R8 standard?

SAE 100R8 is an international standard for thermoplastic high-pressure hoses with specific construction and performance. However, it is primarily used in hydraulics and not in the food and pharmaceutical industries, where FDA and USP Class VI are more relevant.

Can I use the same hose for multiple media?

That depends on the material selection and chemical resistance. Some thermoplastic hoses can withstand alcohol, acids and CIP liquids, while others are limited to specific media. Please contact us for advice.

da

da

de

de

en

en

sv

sv