Milkland Flex

Highly flexible, steel spiral, 6 bar

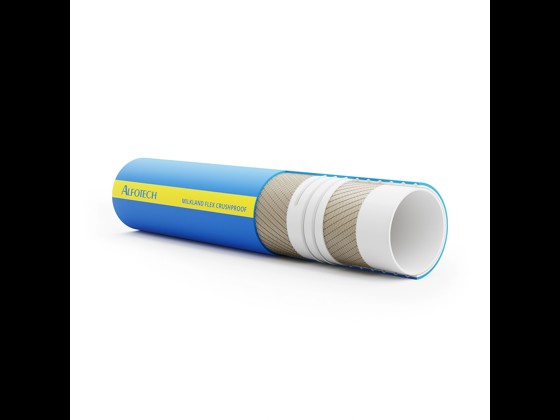

Milkland Flex Crushproof

Impact resistant, highly flexible, plastic spiral, 6 bar

Mastermilk

Suitable for cream, steel spiral, 10 bar

Milkland

Flexible, steel spiral, 6 bar

Milkland Crushproof

Impact resistant, plastic spiral, 6 bar

Everything you need to know about milk hoses

Milk hoses are essential in the food industry, especially in dairy production, where they ensure hygienic and efficient transport of milk products and other similar fatty foods. Throughout the dairy process, milk hoses must fulfil strict safety and durability requirements. From their construction and materials to how to choose the optimal model for your specific needs, we give you the insights here.

What are milk hoses?

Milk hoses are used to transport milk and fatty foods through different stages of production. Natural rubber and NBR rubber are the main materials in our milk hoses, known for their robustness and flexibility. They can withstand high temperatures, pressure and fulfil strict hygiene requirements. Many of the milk hoses we supply to the dairy industry are suitable for raw milk weighing, processing or bottling, for example.

Top choices in milk hoses: What should you look for?

When choosing the right milk hose, it is important to understand the differences in their properties and materials. The differences between the hoses depend especially on the fat content of the medium to be transported.

Milkland Flex

Our Milkland Flex is built around a steel spiral that provides extra flexibility - a feature that gives it its name and makes it easy to handle in everyday dairy operations. The hose is made of natural rubber both inside and out, a construction that ensures long life and resistance to abrasion. It is also designed to withstand a pressure of up to 6 bars during use, making it particularly suitable for weighing raw milk.

Milkland Flex Crushproof

Our Milkland Flex Crushproof milk hose is built around a plastic spiral and impresses with its great flexibility and robust design. It is made of natural rubber and can withstand a pressure of up to 6 bar. As the name suggests, it is ideal for busy production environments with frequent truck and lorry traffic as it is particularly resistant to impact from heavier vehicles - making it the obvious choice for dairies with high demands on durability.

Mastermilk

The Mastermilk milk hose is made of nitrile (NBR) on the inside and durable synthetic rubber on the outside. The material combination creates a rubber quality that is particularly resistant to fatty media. The hose is built around a steel spiral, which not only makes it extra flexible, but also allows it to withstand a working pressure of up to 10 bars. With these specifications, the Milkland model is ideal for cream production and the transport of other fatty liquids under high pressure in dairy production.

How to choose the right milk hose

When choosing the right milk hose, it is crucial to consider the fat content of the products to be moved during dairy production. Products with a high fat content, such as cream, require milk hoses that are resistant to fat to ensure longevity and hygienic transport. High fat content requires the fat resistance of NBR rubber, making the Mastermilk hose with its construction the ideal choice.

When transporting media with lower fat content such as colostrum, hoses made from natural rubber are a sensible choice. Here it is important that you match the material of the hose with the fat content of the product to be transferred to ensure the best result for your dairy. Take a closer look at our Flex series if this is on your agenda.

Have you tried our online hose configurator? Here you can quickly and easily configure your own milk hoses based on dimensions, length and quantity. You can also choose from several different coupling types to ensure that everything fits together with your process plant - in other words, you can customize your very own hose solution based on the specific specifications you may have.

Accessories that extend lifetime

To extend the life of your milk hose, it is wise to invest in accessories that protect and optimize function. Hose guards help minimize unnecessary wear and tear by providing extra protection against abrasion and damage, thereby significantly increasing the lifetime of the hoses. They protect hoses from external influences such as sunlight, chemicals and mechanical damage. By choosing quality guards and ensuring proper hose maintenance, you can achieve more efficient operation and reduce replacement costs.

Our support: How we can help you

Are you looking for the perfect milk hose for your needs, but still not sure where to start? Let our dedicated team guide you to the ideal hose solution that matches your specific requirements. We offer comprehensive technical advice so you can make the right choice with peace of mind. We are here to make the process easy and efficient for you, from start to finish.

Give us a call on +45 7020 0422 or send us an email at inquiry@alfotech.eu. We look forward to helping you find the hose solution that can make a difference in your production.

Frequently asked questions

Which hose should I choose for transporting cream?

When choosing a hose for cream, the material selection should be in focus to ensure safety and efficiency. Cream requires grease and oil-resistant hose, and NBR rubber is ideal with its excellent resistance. This material prevents degradation, extends hose life and ensures reliable transport.

How do you clean milk hoses effectively?

For effective cleaning of milk hoses, it is essential to use an approved cleaning agent that removes milk residues without damaging the hose. Use hot water that can eliminate bacteria, but make sure the temperature does not exceed the hose specifications. A flow-through method is recommended to ensure all residues are removed. Remember to rinse the hoses both before and after use for optimal hygiene.

What certifications do milk hoses need?

Milk hoses must be food approved and fulfil the relevant hygienic standards such as FDA (Food and Drug Administration) and EU Food Contact Materials (FCM). These certifications ensure that the hoses can be used for food production, including in the dairy industry, without releasing harmful substances into the milk.

da

da

de

de

en

en

sv

sv