With December just around the corner, more and more companies in the food and pharmaceutical industries are starting to schedule the year-end service inspection between Christmas and New Year. However, some companies skip it for one reason or another, for example due to heavy workload or finances. Consequently, important technical components in the process plant are not replaced in time, increasing the likelihood of downtime when the new production year starts. In other words, postponing necessary new purchases of technical equipment can be costly in the end.

With more than 35 years of experience as a supplier to the process industry, we know how important it is to keep track of the condition of process equipment, especially during the year-end service inspection. In this newsletter, we therefore focus on several types of technical components that can often be important to keep production running.

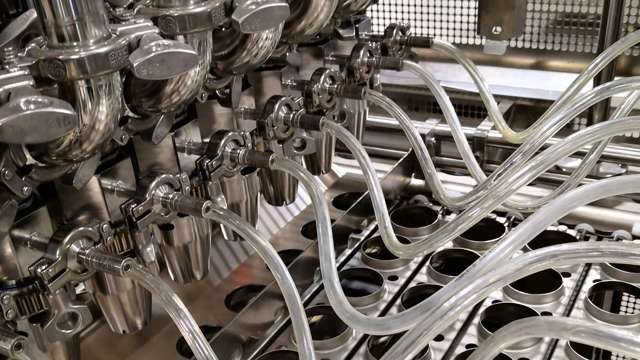

Safety-enhancing equipment for CIP cleaning

CIP cleaning often involves the use of highly alkaline or acidic liquids, such as lye or hydrochloric acid, under higher pressures and temperatures than usual. The process requires great focus on safety for workers - which is why both hoses and couplings should be CIP compatible.

At Alfotech, we recommend the Alichem/SPL and HOT Alichem/BN-S hose models, both of which are extremely durable, even against very harsh chemical fluids. In addition, they can be advantageously combined with Alfotech's InterLock system, which ensures that the hose couplings remain intact in the event of a failure.

Inspect mechanical seals and consider their suitability

If you use pumps on your production line, the mechanical seals should always be checked during the service inspection. In addition, it may be worth considering whether you are using the right ones. We often see customers using mechanical seals that last for less than the prescribed period because they were not suitable for the production in question. For example, we have seen carbon/silicon-based mechanical seals used in a butchery with brine as the medium of production. Unfortunately, this resulted in a production stop because the coal was degraded over time by the saline precipitate from the brine.

Cost-effective alternatives to sight glass

Process inspection is extremely important for many companies involved in the production of food or medicine. It is about being able to monitor the medium in terms of color and substance. Sight glass for piping is often used, but there are also other and more cost-effective alternatives, such as food-grade corrugated Teflon hose or PUR 401 Food for more demanding pressure conditions. Both alternatives offer additional flexibility and adaptability and are ideal for production areas where space is limited. Therefore, you may want to consider whether they would be better suited to your production rather than piping with sight glass.

We can deliver within a few days

Perhaps you are looking to replace your process equipment - or simply buy spare parts? Already, a number of our customers are placing orders in connection with the last service inspection of the year. Right now, we have both sight glass, Alichem, PUR 401 Food and corrugated Teflon hoses in stock. Do not hesitate to contact our sales team via inquiry@alfotech.eu or by phone +45 7020 0422. Our sales consultants can help with advice as well as orders. You can also create a user for our webshop and easily and conveniently order the products yourself.

da

da

de

de

en

en

sv

sv