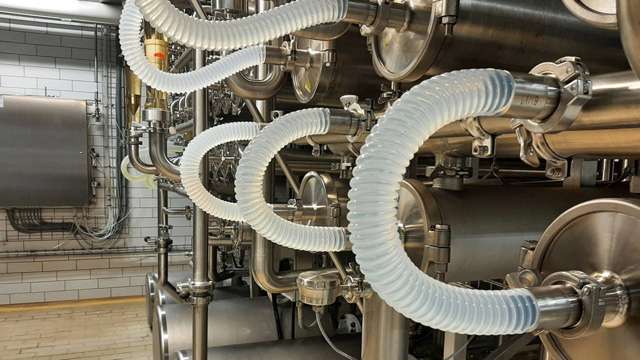

A quick glance may be enough to detect a change in flow. But what do you do when the medium runs in a closed system and inspection requires disassembly? Transparent hoses and sight glass give you visual access while the process is running. Where sight glass serve as fixed inspection points in the pipe run, transparent hoses provide flexibility in connections and circulations.

Whether you detect colour changes, bubbles or particles, you can check flow and consistency without interrupting operation. You get a real-time view of the situation and reduce the risk of errors, contamination and blind troubleshooting.

Read on to see how transparent hoses and sight glass can enhance your visual control!

See the flow with transparent hoses

Transparent hoses make it easy to keep track of what is happening in the process line. During processes such as dosing or vacuum transport, you can check the flow, detect air bubbles or register changes in colour and consistency. And there are several types of hoses that are suitable for the purpose.

- Polyurethane hoses are popular because they combine flexibility, durability and chemical resistance. However, it is worth noting that PU (polyurethane) can change colour over time, especially when exposed to sunlight or UV rays. This means that the material can gradually lose its clarity over time.

- PVC hoses are a good choice for temporary installations. They are transparent, but they have their limitations: they cannot withstand high temperatures or fatty media and can become stiff or discoloured more quickly.

- Teflon hoses or silicone hoses are the obvious choice if you work with chemicals or coloured liquids. They retain their transparency the longest and are resistant to both strong chemicals and high temperatures.

A good choice for sterile applications is our platinum silicone hose without reinforcement. It is made of transparent, platinum-cured silicone and is particularly suitable for environments with high hygiene requirements. Its high temperature and cold resistance ensures that the material retains its shape and performance – even under changing process conditions.

If you work with chemically aggressive media or high temperatures, take a closer look at our clear and smooth teflon FEP hose. It is made of fluorinated ethylene propylene, which can withstand both strong chemicals and extreme temperature fluctuations. With a temperature range from -60 °C to +205 °C, it maintains its performance even in thermal cycles.

If you want to combine strength and flexibility in one solution, our PUR 401 Food is a safe choice. The hose is food-approved and versatile enough for liquids, granules, powders and beverages with up to 20% alcohol. It can also be used for compressed air and pneumatic installations where flexibility and wear resistance must go hand in hand.

When choosing a hose type, you should also consider its service life. If you only need the hose for a limited period, a PVC hose may be sufficient and cost-effective. However, if the solution needs to last over time, you should consider a hose made of silicone, PU or FEP, depending on the nature of the medium and the temperature conditions.

Sight glass: A simple component with a big impact

A sight glass – also known as a viewing glass or inspection glass – is a transparent control point in the piping system that gives you visual access to the medium during operation. It is the fixed reference point that allows you to see what is going on without having to open or disrupt the process. Sight glasses are typically found in process plants where hygiene and documentation are key, such as dairies, breweries or in the pharmaceutical industry. The construction varies, but the principle is the same: clarity, strength and process control.

Some sight glasses are made of shatterproof and splinter-free FEP or PTFE, others in borosilicate glass for high temperature and chemical resistance.

Our in-Line sight glass with weld ends are a versatile choice for both food and pharmaceutical applications. It is DIN, DS, SMS and ISO compatible and comes with borosilicate glass that can withstand CIP/SIP, aggressive chemicals and temperatures up to +280°C. You can choose between EPDM and nitrile seal rings depending on the medium and your needs.

In environments where glass cannot be used, you can safely choose our sight glass in fluorinated thermoplastic. Because the material is shatterproof and splinter-free, you eliminate the risk of glass shards in the production area – while maintaining full chemical resistance. The smooth surface, both inside and outside, makes it easy to clean and difficult for coatings to stick. This preserves transparency, making the solution ideal for both inspection windows and level indicators on tanks. FEP can withstand temperatures from -40°C to +150°C and can be CIP and steam sterilised.

When choosing a sight glass, you should take into account temperature, pressure and coupling type. Borosilicate glass is ideal for high temperatures and pressure – e.g. in CIP/SIP processes – while FEP is ideal in areas where break resistance and chemical resistance are most important. Sight glass is available with threaded, clamp and weld connections, so you can adapt the solution to your existing piping.

One glance and you have the answer

Do you want to follow the flow without stopping the process? Then transparent hoses and sight glass are the answer. You get real-time visual inspection, faster response to deviations, fewer stops and fewer errors.

We are always available if you want advice and deeper insight into your options. Call us on +45 7020 0422 or send an email to inquiry@alfotech.eu – we will take a look at your specific needs.

da

da

de

de

en

en

sv

sv