At the heart of every successful dairy production lies the combination of reliable products, tailored technological solutions and an unwavering dedication to quality.

At Alfotech, we understand the unique demands and challenges faced by the dairy industry. With a rich history of innovation and customer-centric service, we have crafted solutions that not only meet these demands, but also set new standards for efficiency and quality.

Our in-depth knowledge of the dairy industry, combined with our technological expertise, makes us the ideal partner for dairy companies looking to optimize their processes and produce the best dairy products on the market.

Whether it's raw milk weighing, processing or final bottling, we offer the most advanced and reliable solutions designed specifically for your needs.

Milk hoses for weighing in raw milk

The first stage of dairy production is one of the most critical: receiving and weighing in raw milk. This step forms the foundation for all subsequent processes.

At Alfotech, we have the right tools to ensure this phase runs smoothly. Transferring raw milk requires more than just an ordinary hose.

Our Mikland Flex and Mastermilk milk hoses are designed for just this purpose. Designed with high flexibility, hygiene and gentle handling of dairy products in mind, they are both ideal for taste- and odor-free transportation of media, free from contamination and with all natural properties intact.

Our most popular models

Reliable, high-quality stainless steel fittings

In the dairy industry, stainless steel food fittings play a vital role in keeping the milk's path through the system leak-free and efficient. The most common dairy couplings for use in the dairy industry in the Nordics follow DIN, SMS and DS standards respectively.

At Alfotech, we offer a wide range of fittings according to these standards. They are available in AISI 316, which is a high-quality steel that is stainless, acid-proof and has good corrosion and heat resistance. They are also very hygienic and easy to clean with a surface roughness of ≤ 0.8 µ.

Extend the life of wear parts

The process of turning raw milk into different dairy products such as cheese, milk, yogurt or cream is typically complex and requires high precision.

A key part of this precision lies in homogenization, which is the process of making a mixture uniform or homogeneous. This process is particularly important in the food industry, where it ensures that milk maintains an even consistency and quality.

As with all industrial processes, wear and tear on machinery and other components is inevitable. That's why we offer hard metal coating of various wear parts, including pistons for use in your homogenizers. With hard metal coating, the lifespan of your wear parts is significantly increased and the need for frequent replacements is reduced.

Typical parts for hard metal coating

Advantageous solution for filtration

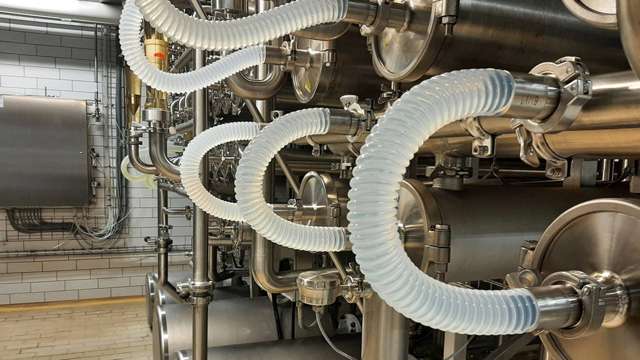

For one of our largest dairy customers, we encountered a challenge with their filtration system. The solution of replacing their process pipes with our Teflon corrugated hoses brought several benefits:

- Transparent material for better flow monitoring

- Spiral shape for high flexibility and thus adaptability

- PTFE as a material for a wide temperature range

With the combined flexibility and durability of this hose type, the customer benefited from easier inspection of the filtration system, easier adaptation to the system's filter connections during operation, and the wide temperature range PTFE supports.

Cleanliness is crucial in the dairy industry for both product quality and safety standards. With this in mind, we offer a range of specialized products for low-pressure systems, such as our easy-to-handle Clean Wash low-pressure rinse hose.

Our range, which includes durable hoses and efficient spray guns, is designed to ensure consistent and thorough cleaning of your equipment.

To maintain an efficient workflow and order in the workplace, we also recommend our hose reels for easy and convenient organization.

Furthermore, it is important to have different nozzles for e.g. spray guns, as different cleaning tasks require different water flow patterns to achieve the best results.

For heavily contaminated surfaces or hard-to-reach dirt, our spray ball for mounting on a connection is an excellent choice.

Popular cleaning products

Bottling/filling

For bottling/filling products, precision and hygiene are essential. Whether it's milk, cream, yogurt or any other dairy product, we offer compatible hose solutions of the highest quality.

Our Dynamic CLC hose is particularly well suited for the purpose. With a robust construction that meets the hygienic standards of the dairy industry, this hose ensures that every product is filled accurately, quickly and without spillage.

In addition, our silicone hoses and Beverage CLC hose are also popular choices for bottling/filling. Among some of our customers, the Beverage CLC is used to add jam to yogurt products.

Documentation, approval and standards

In the dairy industry, compliance with documentation, approvals and standards is not just a legal requirement - it's also essential for consumer confidence and safety. With milk and dairy products being a daily part of many people's diets, it's important that we can ensure the quality and safety of our products.

We understand the importance of complying with both local and international standards. To ensure that our products are safe and of high quality, we strictly follow the guidelines set by the FDA (U.S. Food and Drug Administration). In the European market, we strictly follow the directives and regulations set by the EU, in particular EC 1935/2004 and 2023/2006/EC.

da

da

de

de

en

en

sv

sv