DS & SMS dairy fittings, weld on

Elbows, tees, hose connections etc.

DIN dairy fittings, weld on

Elbows, tees, concentric reducers etc.

DS union parts

Nuts, weld ons, expansion liners etc.

SMS union parts

Nuts, weld ons, expansion liners etc.

DIN union parts

Nuts, weld ons, blinds etc.

Clamp union parts

Clamp rings, liners, blinds etc.

DIN Clamp union parts

Clamp rings, liners, blinds etc.

MINI Clamp union parts

Clamp rings, liners, blinds etc.

Tri-Clamp ASME-BPE union parts

Liners made of stainless steel

Clamp ring with spring

Stainless steel AISI 304, robust & user-friendly

RJT union parts

Nuts, male weld-ons and weld-on liners

IDF union parts

Nuts, weld-ons, liners

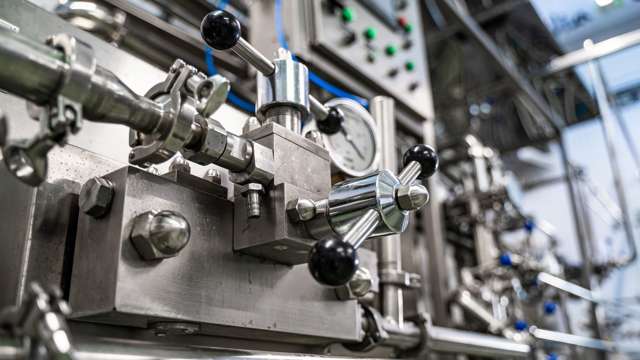

Stainless dairy fittings for the process industry

We stock a wide range of stainless dairy fittings designed to meet the high liners of the pharmaceutical, food and chemical industries. The range includes everything from union parts and welding fittings to hygienic clamp solutions. With our fittings, you can be sure of achieving safe and flexible connections in your pipe system, whether it involves liquids, steam or powder.

What are dairy fittings?

Dairy fittings are a central part of any process plant because they ensure tight connections between pipes and hoses, thereby maintaining hygiene and product safety. Our range covers everything from pipes, elbows, equal tee and crosses to unions in DS, SMS, DIN og IDF as well as the popular Tri-clamp solutions. Tri-Clamp fittings (DIN 32676) have become one of the most widely used solutions in modern process plants because they combine simple installation with high hygiene and reliable operation. The construction has been developed to meet the liners of food production and the pharmaceutical industry and makes it possible to carry out CIP og SIP procedures without any problems. When process lines need to be adapted or cleaned, the connection can be quickly loosened, minimising downtime and making it easier to maintain a high level of hygiene.

The difference between a threaded connection and a clamp connection is that clamp fittings allow quick assembly and disassembly without the use of special tools. This means shorter downtime, easier cleaning and an overall improvement in operating economy.

Materials and surfaces

The choice of material is a crucial factor for fittings used in hygienic processes. That is why the majority of our dairy fittings are made of acid-proof stainless steel AISI 316L. This alloy has a high resistance to corrosion and can withstand contact with both aggressive cleaning agents and various types of media without losing strength or hygienic property. For components that are not in direct contact with the product, such as pipe clips or nuts, we use AISI 304.

We supply fittings with a surface roughness of Ra < 0.8 µm as standard. For medical and biotechnological processes, we can supply fittings with a surface roughness of Ra < 0.4 µm. A smoother surface further reduces the risk of bacterial accumulation and makes cleaning even more effective.

Standards and compatibility

We manufacture dairy fittings in accordance with a number of international standards, which ensure both compatibility and operational reliability:

Pipe standards:

- EN 10357 – the current European standard

- DIN 11850 – previous standard, replaced by EN 10357

- ISO 2037 – previous international standard, still used as a reference

Union standards:

- DIN 11851 – classic hygienic union

- DIN 11864 – aseptic couplings

- DIN 11853 – hygienic couplings

Clamp standards:

- DIN 32676 – standard for tri-clamp fittings

- BS 4825 – British standard for clamp components

These standards ensure uniform dimensions and tolerances, so that fittings from different suppliers can be combined without compromising on tightness or hygiene.

Quality, documentation and special solutions

We attach great importance to quality, documentation and traceability. Each fittings is supplied with a batch number, which makes it possible to trace the product all the way back to production. On request, we can provide certificates and documentation so that you can be sure that the fittings you receive meet the applicable liners and standards.

If you cannot find the right solution among the dairy fittings in our range, we have many years of experience and a proven track record in tailoring solutions for our customers. We have often designed specialised products using our manufacturers' years of experience and innovative thinking to create solutions for our customers that have led to groundbreaking optimisation in their dairy production.

Frequently asked questions

What types of dairy fittings are available?

The most common are clamp fittings (Tri-Clamp), union couplings (DIN, SMS, DS, IDF) and threaded and welding fittings. The choice depends on process requirements, hygiene needs and the standard system on which the plant is built.

What materials are used for dairy fittings?

AISI 316L stainless steel is almost always used for product contact, as it can withstand both aggressive cleaning agents and steam. Components without product contact, such as nuts and pipe holders, are often made of AISI 304.

How can you ensure that fittings are cleaned properly?

Fittings are typically cleaned using CIP or SIP processes. The smooth surface and standardised joints make it possible to remove product residues effectively without dismantling. For highly sterile processes, electropolishing to Ra < 0.4 µm is often used.

Can dairy fittings be combined with hoses?

Yes, dairy fittings can be connected to flexible plastic or rubber hoses via hose tail, as long as the hose is food-approved. This is often used for temporary connections, CIP hoses or tapping functions.

da

da

de

de

en

en

sv

sv