Strainer, Y-type, weld ends

Made of stainless steel AISI 316L/EN 1.4404

Strainer, Y-type, weld ends (DS/SMS)

Made of stainless steel AISI 316L/EN 1.4404, ISO

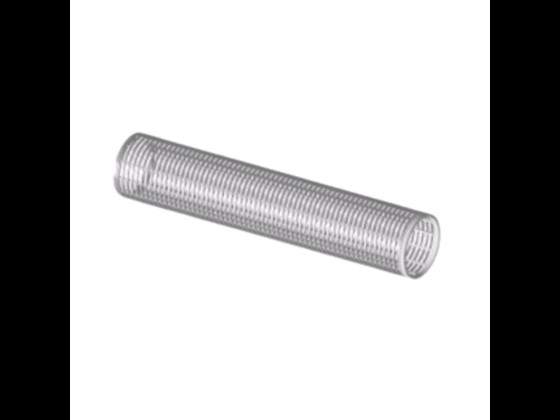

Insert for strainer, Y-type

Made of stainless steel AISI 316

Strainer, L-type, weld on

Made of stainless steel, suitable for liquids

Insert for strainer, L-type, perforated

Made of stainless steel AISI 316

Insert for strainer, L-type, slotted

Made of stainless steel AISI 316

Strainers for process systems – features, types and inserts

Strainers play a crucial role in protecting process equipment from harmful particles and impurities in liquids. In both food and pharmaceutical production environments, it is essential that fluid flows remain clean and unobstructed. When unwanted particles reach pumps, valves or measuring instruments, this can lead to operational disruptions, increased wear and, in the worst case, production stoppages. By capturing and removing these particles, strainers maintain a consistent flow profile and ensure optimal operating economy. We offer filters that combine effective filtration with easy maintenance and high hygiene standards.

Differences between Y-type and L-type strainers

We offer both Y-type and L-type strainers in acid-proof stainless steel AISI 316L. The Y-type has a characteristic Y-shape, where the flow is directed inside the filter. This geometry makes it an effective solution that protects pumps, heat exchangers and other process equipment against foreign matter.

The strainer is made of stainless steel AISI 316L and is available with weld ends, clamp or DS/SMS connection in sizes from DN 25 to DN 100. The insert, which is made of AISI 316, is available in three finenesses of 1 millimetre, 0.5 millimetre and 0.25 millimetre and can be replaced without tools. The dimensioning is based on the filter's KV value, which indicates the amount of water that passes at a pressure drop of 1 bar.

The L-type has been developed for low-viscosity liquids such as water, steam and liquid foodstuffs and beverages. The right-angle design makes the filter compact and space-saving, while the flow runs from the outside in, significantly reducing resistance. With a slotted insert, the flow rate can be increased by up to 75 per cent compared to conventional filters. The inserts are robust, pressure-resistant and can be replaced without tools up to a size of 4 inches. During cleaning, an integrated scraper ring automatically removes deposits, and for more complex processes, pipe combinations are available that allow replacement without interrupting operation.

The strainer is supplied with weld ends as standard, but is also available with DS, SMS, DIN or ISO clamp connections. All parts in contact with the medium are made of AISI 316L (1.4404), while other parts are typically made of AISI 304L (1.4307). The inner surface has a roughness of less than Ra 0.8 micrometres, while the outer surface is electropolished. The working pressure is PN10 for sizes from 1–4 inches and PN06 for 5–6 inches.

Select the right filter insert for your needs

When selecting a filter insert, you should take into account the properties of the process medium, particle size and flow rate requirements. For the Y-type, inserts are available in AISI 316 in three finenesses: 1 millimetre, 0.5 millimetre and 0.25 millimetre.

There are two variants for the L-type. The slotted insert in AISI 316 is available with openings from 50 micrometres to 4 millimetres and combines high filtration efficiency with low resistance. In addition, we offer filter inserts with holes, also in AISI 316, designed for processes with high particle loads, steam or return flow from CIP systems.

All strainers are supplied with standard gaskets in FDA-approved EPDM, but Viton or PTFE can also be selected depending on the process medium and temperature. Media-wetted parts of the filters are made of AISI 316L, while components without direct media contact are typically made of AISI 304L. The inner surface has a roughness of less than 0.8 micrometres, and the outer surface is electropolished to ensure easy cleaning.

Frequently asked questions

What is the difference between Y-type and L-type strainers?

The Y-type has an angled construction with low pressure drop and high flow, while the L-type has a right-angle and compact design that is well suited for installations with limited space.

When should the filter insert be replaced?

The filter insert should be replaced or cleaned when there are signs of reduced flow or clogging. Scheduled maintenance ensures stable operation and reduced downtime.

What material are the filter inserts made of?

All filter inserts are manufactured in AISI 316 stainless steel and are designed to withstand aggressive media and frequent cleaning in hygiene-sensitive environments.

How do I install a strainer correctly?

The strainer must be installed in the specified flow direction and positioned so that the insert is easily accessible for cleaning and replacement. Connections are available as weld ends or in standards such as DS, DIN or ISO clamp.

da

da

de

de

en

en

sv

sv