Elbow 90°, DIN tube, weld on

Elbow 90°, ISO tube, weld on

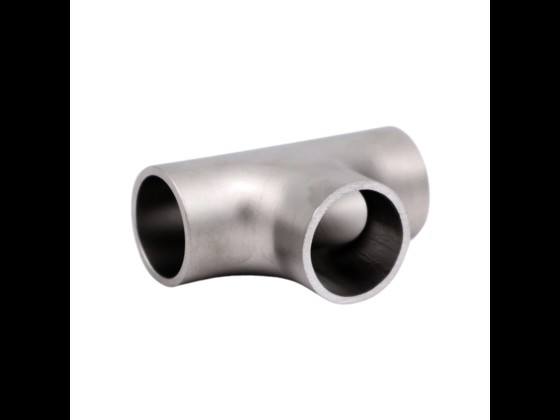

Tee, DIN tube, weld on

Tee, ISO tube, weld on

Tee, ISO tube, short, weld on

Reducer, concentric, ISO

Create secure pipe connections with stainless steel welding fittings

In the process industry, stainless steel welding fittings play a crucial role in the production of various types of chemicals, food and pharmaceutical products. Stainless steel welding fittings are pipe connections used to join pipes and other pipe fittings together. These fittings are specially designed to ensure a tight and stable connection that can withstand the high pressures and temperatures often present in the industry. Welding fittings are ideal for creating permanent pipe systems that can last for many years and minimize the risk of leaks or other issues that can affect production processes.

Different types of welding fittings

At Alfotech, we offer a variety of stainless steel welding fittings, including our range of elbows, tees and concentric cones. The different types of welding fittings each have their own characteristics that can be utilized through collaboration with Alfotech.

- Elbows are an important part of any piping system and are often used to guide pipes in different directions. Stainless steel weld bends are available in different degrees of bend, from 45 to 90 degrees, and can also be customized for specific production requirements. These bends are usually welded onto the pipes, ensuring a secure and tight fit and reducing the risk of leaks.

- Tees are another type of stainless steel welding fittings that are relevant in many piping systems in the process industry. Tees are used to connect three pipes or parts of the piping system in a T-shape, allowing liquids or gases to flow in different directions. These fittings can also be adapted to specific production requirements and thus form part of unique solutions in your process plant.

- Reducer - concentric is a type of stainless steel welding fitting used to connect two pipes of different diameters or sizes. These fittings are designed with a cone-shaped transition that gradually reduces the diameter of the pipe. Stainless concentric cones are usually welded onto the pipes, ensuring a tight fit and reducing the risk of leaks.

Benefits of using welding fittings

Our welding fittings are made from AISI 316 stainless steel, which offers a number of benefits. Firstly, stainless steel is highly corrosion resistant, meaning it can withstand the challenges of aggressive chemicals and high temperatures. This is especially important in the process industry, where chemicals often need to be transported through piping systems.

Another advantage of stainless steel welding fittings is their ability to withstand high pressure and heat. This makes them ideal for applications where a high degree of precision and durability is required, such as in pharmaceutical production or the petrochemical industry. Stainless steel welding fittings can also withstand vibrations and pressure fluctuations, which is crucial in industries where there is a high risk of mechanical stress on piping systems.

Choose the right welding fittings

At Alfotech, we specialize in providing high-quality stainless steel welding fittings that meet the high standards required in the process industry. Our expert team can help guide you through the selection of the right welding fittings to suit your specific production needs. We offer a wide range of welding fittings, including elbows, tees and concentric cones, carefully selected to meet the requirements of different production environments. We offer welding fittings in different standards, such as DS & SMS (ISO) and DIN welding fittings.

If you would like more information about our stainless steel welding fittings, please contact us at alfotech@alfotech.dk or by phone +45 7020 0422. Our skilled team is ready to answer your questions and help you find the best solutions for your business.

da

da

de

de

en

en

sv

sv