Push-in male connector

Made from POM, complies with EC 1935/2004

Push-in male swivel elbow

Made from POM, complies with EC 1935/2004

Push-in male swivel elbow, BSPP

Made from POM, complies with EC 1935/2004

Push-in male swivel tee, BSPT

Made from POM, complies with EC 1935/2004

Push-in male swivel tee, BSPP

Made from POM, complies with EC 1935/2004

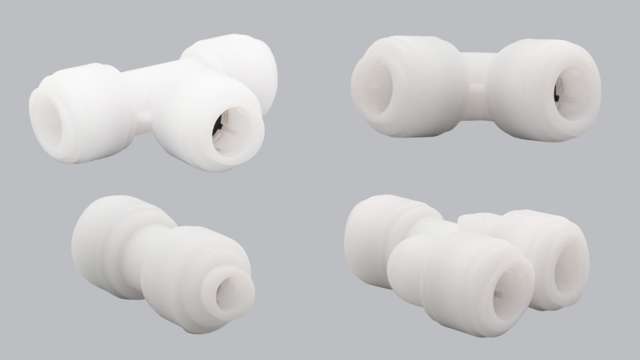

Push-in union connector, reduction

Made from POM, complies with EC 1935/2004

Push-in union connector

Made from POM, complies with EC 1935/2004

Push-in union elbow

Made from POM, complies with EC 1935/2004

Push-in union tee

Made from POM, complies with EC 1935/2004

Push-in Y-union

Made from POM, complies with EC 1935/2004

Push-in fittings in POM (Polyoxymethylene) – a simple solution for compressed air systems

Push-in fittings in POM (polyoxymethylene) offer you a practical, economical and hygienic solution for connecting compressed air hoses. They are particularly suitable for light pneumatic installations in the food industry, chemical production and pharmaceutical plants – especially in areas without high temperatures or aggressive cleaning.

The robust plastic material makes the solution easy to handle, while the tool-free connection ensures quick installation. The couplings are designed for dry and clean environments where simple maintenance and good operational reliability are priorities.

Suitable for clean and stable operating conditions

Our push-in fittings are made of POM – a technical plastic material with high rigidity and good wear resistance. The material is particularly well suited for compressed air systems where the installations are not exposed to aggressive media, high temperatures or CIP cleaning. All fittings are equipped with an integrated EPDM gasket, which ensures a tight connection to the hose and effective sealing during operation. The combination of POM and EPDM provides a solution with low weight, a corrosion-free surface and good tightness without the need for complicated maintenance.

Quick installation – no tools required

Push-in fittings are designed to make installation and maintenance as simple as possible. The hose is pushed directly into the fitting, where an internal locking mechanism secures it automatically. At the same time, the gasket ensures a tight and secure connection.

During installation:

- Cut the hose at a right angle and without deformation

- Push the hose in until you feel it lock into place

- Check the tightness and pull test the fitting if necessary

When dismantling:

Press the release ring inwards and pull the hose free. This saves time – especially in systems with many connections or frequent replacements.

Find the right push-in fitting for your task

You can choose between several designs and sizes, so you can easily adapt the design to your compressed air system. Whether you need to extend a hose or create a branch in a more complex system, you will find a variant that matches your needs.

Push-in T-fittings

Use T-fittings when you want to connect three hoses – either with the same or different dimensions. You can choose models with three push-in ports or variants with threaded ports, depending on your system solution.

Straight and reducing fittings

If you need to connect two hoses with the same diameter, choose a straight fitting. If your hoses are different sizes, the reducing models give you flexibility – especially when space is limited or the flow needs to be adjusted.

Push-in male elbow fittings

If you want to change the flow direction at a 90° angle without bending the hose, male stud elbow fittings are the obvious solution. You can choose between versions with two push-in ports or combinations with BSPP threads.

All fittings are compatible with standard compressed air hoses and comply with industry standard dimensions – so you can easily integrate them into your existing systems.

Where does POM fit best?

The right choice of material is important for both performance and total cost. POM is the obvious choice when working with:

- Compressed air in dry, clean and moderate environments

- Pneumatics in non-aggressive zones

- Lighter applications without chemical exposure

POM is not suitable for:

- High temperature or steam

- CIP cleaning with acids or bases

- Contact with aggressive chemicals

In these cases, we recommend stainless push-in fittings, which can withstand cleaning, pressure and chemical stress. You get greater robustness, but also a different price structure. In return, you will have fewer replacements and more long-term operation – especially in installations close to product zones or in demanding environments.

Why many choose fittings in POM

-

Easy and quick installation

Provides lower installation time and less downtime

-

Lightweight and easy-to-clean construction

The plastic material is easy to handle and resistant to moisture

-

Reliable sealing with EPDM

Stays tight – even with repeated connections and disconnections

-

Flexible variants for different needs

Connect straight, angled and branched connections

Ready to choose fittings?

If you are unsure which type is best suited to your installation, we are happy to provide technical advice. We are familiar with both the requirements of the food industry and the practical considerations of chemical and pharmaceutical plants – and can help you find a solution that works in practice.

Contact us on +45 7020 0422 or by email at inquiry@alfotech.eu if you would like to know more.

Frequently asked questions

What is a push-in fitting in POM?

A push-in fitting is a type of coupling used to connect compressed air hoses in process plants. The fitting is made of POM (polyoxymethylene) and is installed by pushing the hose directly into the port. An internal EPDM gasket ensures tightness.

How do I remove a push-in fitting?

Press the release ring inwards and pull out the hose. Always remember to shut off the air supply first to avoid accidental blowouts.

When should I choose push-in fittings in POM?

When you need a lightweight, economical and hygienic solution in dry and clean environments – e.g. when connecting compressed air to pneumatics in process plants.

Is there a difference between push-in and push-on fittings?

Yes. Push-in fittings are connected via an internal locking mechanism and o-ring. Push-on fittings are pushed onto a grooved hose tail and secured with a nut – typically without an internal gasket.

da

da

de

de

en

en

sv

sv